A company’s economic activity will determine the type of warehouse it needs. Similarly, although all warehouses share common characteristics, the product to be stored will determine the design and construction of both the warehouse and the installation of storage systems.

In addition, the nature of the product will condition the reception of goods, their verification, transport between the various warehouse areas, storage of goods, order preparation, consolidation of loads, shipment of goods and stock management. However, not all goods are the same, so neither is their type of storage nor the logistics processes that they involve.

Definition of unit load

Before explaining the existing types of load based on different criteria, it is important to remember what a unit load is. As already communicated in the "Types of pallets and uses" post, the unit load is a homogeneous grouping of a set of products arranged on a support or platform that facilitates the handling and transfer of goods and which therefore acts as a logistical unit as such.

The purpose of the grouping of the load is to reduce the number of movements to a minimum, in order to facilitate its transport and storage.

Types of load can be classified in various ways:

Types of load according to their recording

General load

These are goods that require individual packaging. They can be handled in 2 different ways: firstly, there are those loads that can be handled individually, and, secondly, there is the general unitised load, i.e., loads which for their handling during the logistics process are unified on supports such as boxes, pallets or containers.

In both cases, the total load is recorded in units.

Bulk load

This is the load that is not recorded in units, but rather by mass and volume criteria, since these are goods prepared for transportation directly, where the means of transport itself acts as a container, generally specialised containers.

In other words, these goods travel loose, without any packaging. For example, normally gases, liquids or similar substances, which by their nature are difficult to package.

Types of load according to their volume

Small loads

These are loads that can be carried in one hand and that are generally unified in a single package. For example, cartons of juice or packs of beer.

Medium loads

They are slightly bigger than the above loads and may weigh up to 10 kg, but they can still be carried by hand.

Both small and medium loads can be stored in Carton Flow Rack systems and Longspan Shelving. Although there are differences between these two types of picking solutions, both are optimal for these types of products which can be handled manually due to their volume and weight.

In Carton Flow Rack systems the priority is to facilitate high product rotation (for example, the warehouses of food distribution chains such as Eroski and Caprabo), while with Longspan Shelving, what is sought is direct access to the goods (for example, the warehouse of textile company Grup Sevica).

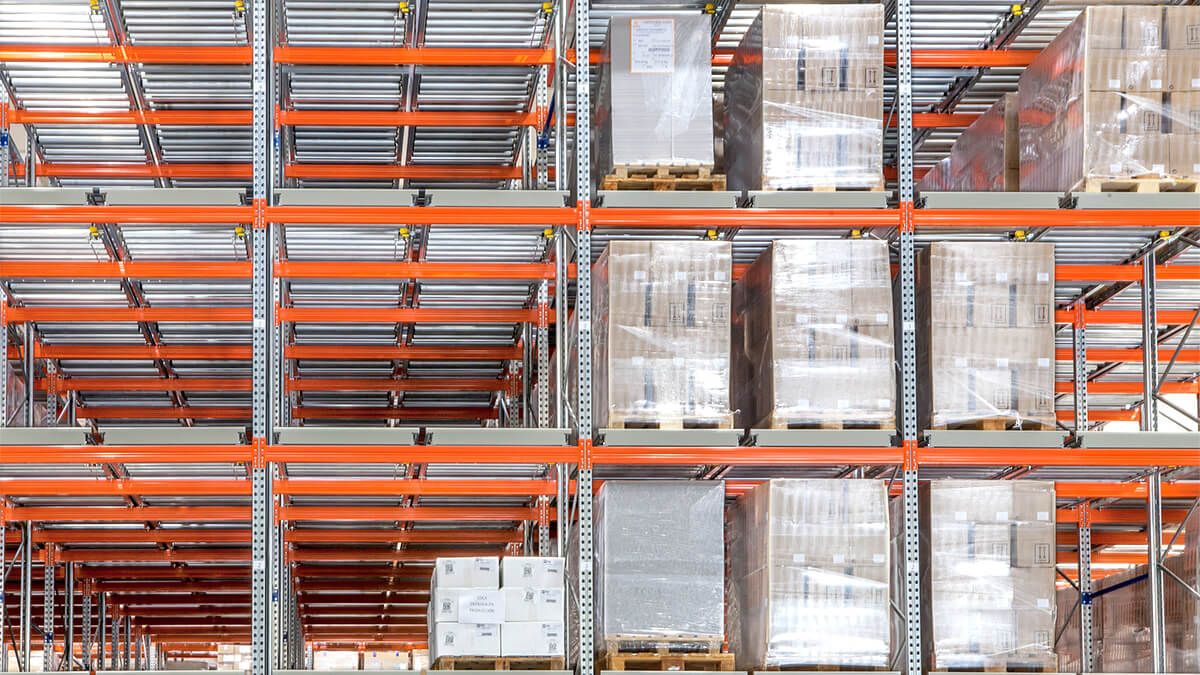

Large or pallet loads

These are larger goods which require standardised packaging and are grouped on a pallet for handling. This type of load cannot be handled manually, but by mechanical means such as forklifts, etc.

The pallet load can be stored with a wide variety of storage solutions. Everything will depend on the function of the warehouse, the type of product, the available area, etc.

Some companies need immediate access to goods in their daily intralogistics operations. In such cases, the warehouse will be equipped with storage systems with direct access to the pallets.

However, other companies will prioritise the maximum optimisation of the available space, both floor and height, so compact and high-density storage systems will be the most appropriate solution.

Bulky loads

These are large loads that sometimes cannot even be stacked. They can range from large appliances such as refrigerators to construction items such as iron girders.

When loads are very bulky, like above, special mechanical equipment such as cranes are needed to move them.

Cantilever Racking may meet this large load storage need.

Special size loads

These are exceptionally large and almost always very heavy loads (such as structural elements for the building of bridges), which even exceed the size of transport vehicles and require support vehicles, special traffic arrangements for their transport, etc.

Types of load according to their weight

- Light loads: these are loads that do not exceed 5 kg.

- Medium loads: these types of goods have a minimum weight of 5 kg and maximum of 25 kg per unit load.

- Heavy loads: in this case, the weight ranges between 25 kg and one ton.

- Very heavy loads: over one ton.

Types of load according to the useful life of the product

There are two types of load in this category:

Perishable load

Products with a limited useful life or determined by an expiry date, such as fresh foods. This requires completing the logistics process in a set period of time and a storage that facilitates stock rotation.

Storage of perishable products must be under specific conditions until their shipment.

Non-perishable load

Products whose useful life does not determine the way the load is transported, received, stored and shipped.

Types of load according to their resistance

They can be classified into three groups:

Resistant loads

These are those loads that can support weight on top of them, i.e., they allow the stacking of the product, either of the same type or supporting the load of another type of product.

Light loads

These loads can be stacked on top of each other, but establishing limits.

Fragile loads

They must be handled with special care given that, due to their nature, they could be damaged or spoiled. They must be stored individually on the racking because they cannot be stacked.

Types of load according to their dangerous property

These are goods that require specific handling, otherwise they could endanger human life and their means of transport. These products are characterised by having explosive, combustible, oxidising, poisonous, radioactive or corrosive properties.

Depending on their degree of danger, the United Nations (UN) establishes nine classes of dangerous goods:

- Explosives

- Gases

- Flammable liquids

- Flammable solids

- Oxidising substances and organic peroxides

- Toxic and infectious substances

- Radioactive material

- Corrosive substances

- Miscellaneous dangerous substances and articles

Some of these products can be stored conventionally according to special criteria. This is the case with the storage of chemicals, whose risks must be considered when configuring the logistics centres and industrial racking that will store their stock.

Types of load according to batch

- Unit load: products whose batch consists of a single unit of goods.

- Loads stored in batches: Depending on the type of product, batches will comprise different units of goods. That is to say, the batches of a dairy products load will not consist of the same number of units as a batch of tiles.

These categorisations of goods are not unique and others could be added. In addition, the characteristics indicated in each category are compatible with the specifications of others: a load may be light resistance, stored on a pallet by its volume and grouped into a batch of 24 units of goods.

More important than the actual categorisation of the goods is knowing how it needs to be treated throughout its useful life-cycle: from its manufacture to its sale to the end user, including also transport conditions and storage needs.

In AR Racking we will help you to find the right industrial racking to make the most of the space in your warehouse and store the product in optimum conditions. Please request more information by clicking here and our team will advise you on the best storage solution for your warehouse.