Clad Rack Warehouses

Clad Rack Warehouses are comprehensive storage systems which can be made up of any type of storage system as their main feature is for the racking to form part of the building structure.

These types of warehouses stand out for their optimisation of storage at height and their versatility, since they can be designed based on different solutions and adapted to specific customer needs.

In this system, the racking not only supports the load of the stored goods, but also the load of the building envelope, as well as external forces such as wind or snow. For this reason, civil engineering work is minimal, which speeds up assembly and reduces costs in relation to traditional construction systems.

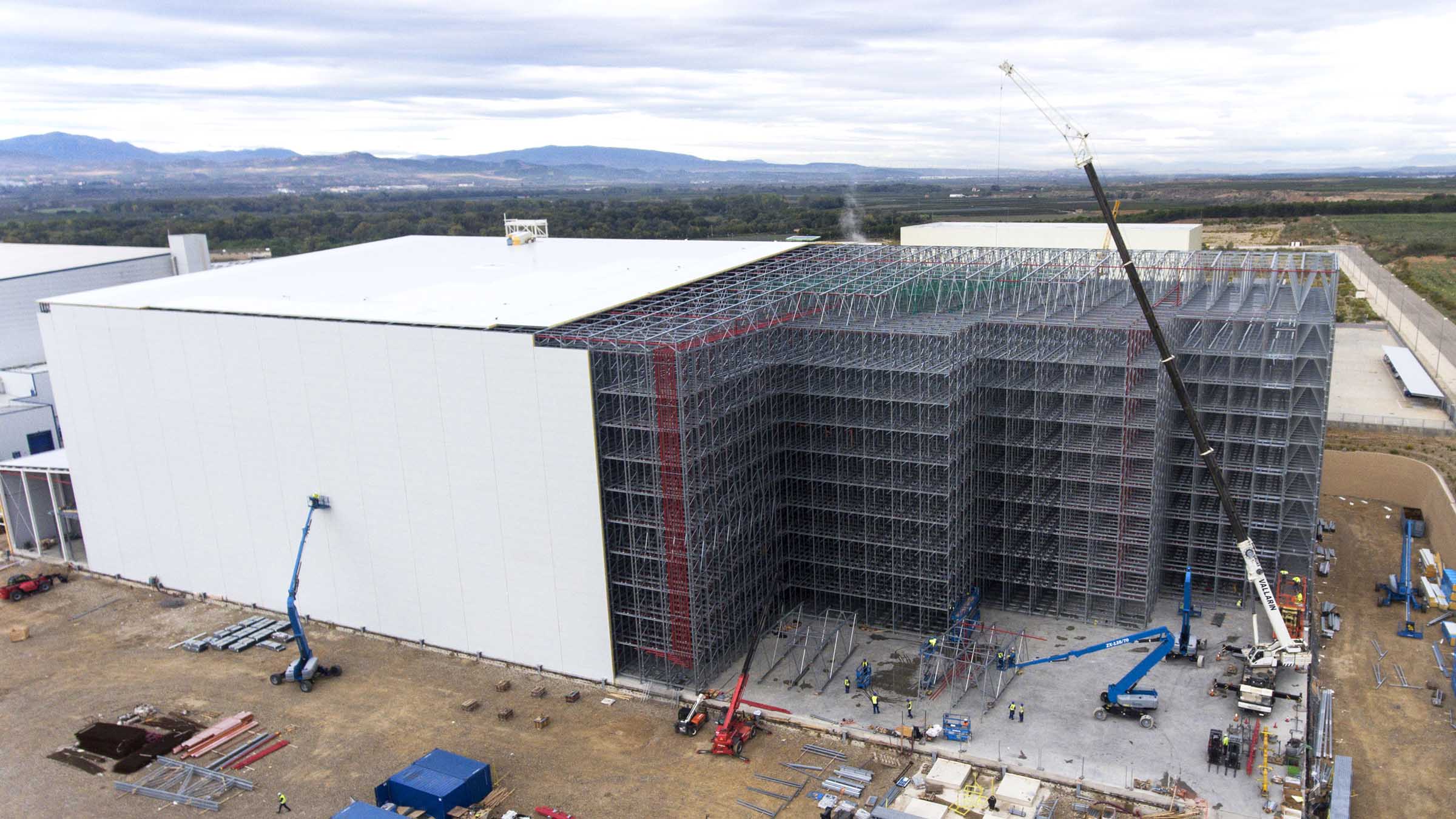

This is the reason why Clad Rack Warehouses exploit the available space in the warehouse, and can therefore reach heights of over 40 metres: in the construction process, first the racking is assembled, and then the building envelope is built around this structure until the warehouse is complete.

The clad-rack warehouse is a high-bay storage solution, in which the racking supports, in addition to the load of the goods, the load of the side and roof cladding of the warehouse, forming a compact assembly. In other words, in this type of warehouse the racking supports the structure itself.

A clad-rack warehouse is designed to support the storage unit loads, and protect against varying climatic effects that may arise such as wind, snow and seismic movements, corresponding to the location of the warehouse.

Therefore, most clad rack buildings are equipped with automated systems and robotic equipment for the handling of goods, especially of if they are multitier.

These warehouses make it possible to fully exploit and automate storage space at height, in addition to offering excellent adaptability in terms of space, loads and weights. This optimises the available volume, reaching great storage heights.

In any case, this does not prevent clad-rack warehouses from being subject to safety and quality standards specific to the structures. For this, AR Racking complies with the EN-1090 CE marking standard, mandatory for all manufacturers of clad rack industrial steelwork structures installed in the European Community, as established in Regulation 305/2011 of the European Parliament.

Clad Rack Warehouses

In a clad-rack warehouse, loads are stored using racking specifically designed to support the stored loads and form part of the building structure, as well as external forces such as wind and snow. Most of them are automated systems that use robotic equipment for load handling.

It is important to point out that the load is organised in such a way as to maximise operational efficiency. Additionally, racking selection and load distribution can be tailored to the specific needs of the product type and customer requirements.

Although the image of these warehouses is associated exclusively with automated systems, in reality, these technologies can be implemented in different types of racking, including adjustable, compact, cantilever, live storage and even those intended for light loads distributed over several floors.

For all these reasons, the clad-rack warehouse is the most suitable solution for high bay storage, also avoiding civil works.

Clad-rack warehouses manage to provide a high load density, which means significant savings due to the lower investment.

The system adapts perfectly to warehouses that require cold storage or freezing chambers.

Types of Clad Rack Warehouses

Single Deep

Double Deep

Multi-Shuttle

Main advantages and features of the Clad Rack Warehouses are:

- Optimum use of space at height. Clad-rack warehouses are high-bay storage solutions, which allow you to optimise the available space by building warehouses up to 40-45 m high.

- The incorporation of automated mechanical equipment such as stacker cranes and conveyors help minimise the space required for work aisles, thus providing more available storage space.

- The various automated systems facilitate the flow of goods, being faster and more effective, optimising the performance of the logistics facility and generating significant time and cost savings.

- Maximum endurance capacity. The construction of these warehouses is very robust and strong in order to withstand external factors such as wind, snow or seismic movements.

- Simple and quick installation of the warehouse: For the construction of a clad-rack warehouse, it is not necessary to build a high-bay facility to house the warehouse, so there is no need to have a building to house the building.

- Cost savings: The investment in a clad-rack warehouse is less than that of a warehouse with traditional racking, for high-bay storage solutions.

- Ideal for cold storage. These warehouses adapt to low temperatures, making them appropriate for installing cold stores and freezing chambers for the storage of goods. Likewise, the installation of galvanized racking provides greater protection against corrosion, greater durability and lower risk of structural damage.

- Great versatility: Each project is unique which is why clad-rack warehouses are tailored to different customer needs. Therefore, the interior design adapts to different storage solutions to guarantee maximum productivity.

Main applications of clad-rack warehouses

These are the main situations where the use of a clad-rack system is recommended:

- For sectors and companies that receive a wide variety of references and need to store large volumes of an incredible variety of products on pallets.

- When the warehouse is more than 15-20 m high.

- Companies that require maximum optimisation of space and volume, regardless of construction height.

- Companies that need to store their products in cold stores or freezing chambers. A very common option is to install clad-rack warehouses at low temperatures, for which AR’s galvanised racking has an ideal anti-corrosive resistance for this type of environmental conditions.

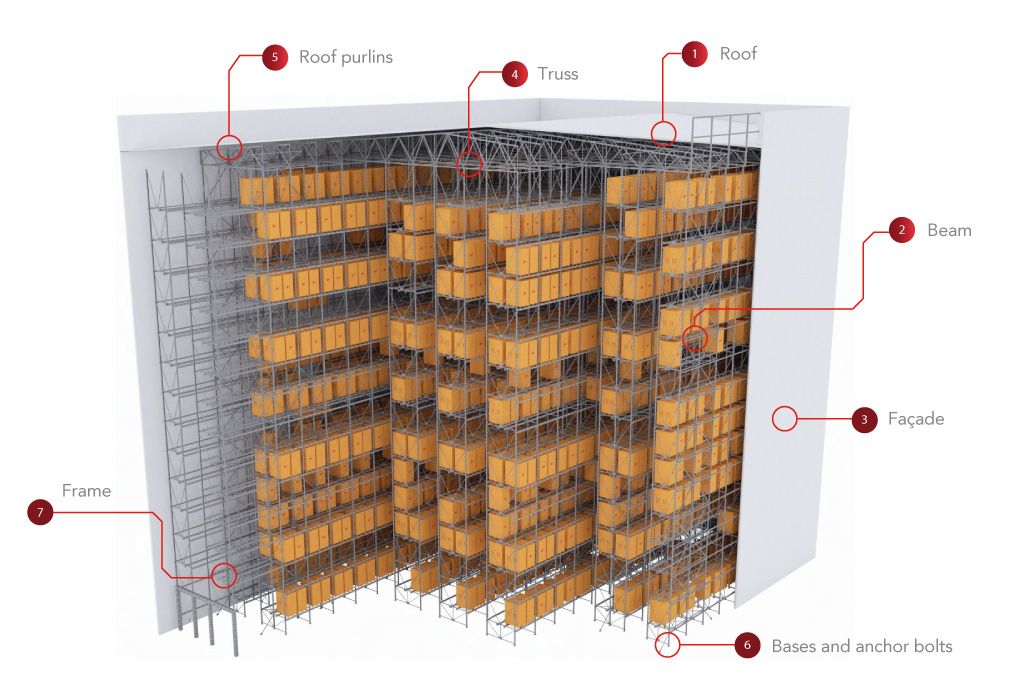

Clad Rack components and accessories

The main feature of a clad-rack warehouse is that its racking is able to withstand not only the stored loads and the forces exerted by the handling equipment, but also other structural elements such as the cladding and the racking that occupies the total height of the interior of the building, as well as different external influences such as wind, excess snow, seismic movements, etc.

It is also essential to build a slab with adequate load capacity to withstand both the weight of the goods and the handling equipment.

Clad-rack warehouses have different design options depending on each customer’s specific needs, these would be some of its components that accompany the structure of the industrial racking.

Main components of Clad Rack Warehouses

Façade and roof

The façade and the upper deck form the outer face of each clad-rack warehouse. Both are seamlessly integrated with the interior metal structure to ensure the highest quality standards combined with a high degree of design freedom.

AR Racking has the ability to realise complex designs that integrate the racking and the external facade.

Beam

Beams play a key role as structural elements in racking systems.

These horizontal components are connected to the uprights and help support the unit loads.

Truss

A truss is a structural element typically used in roof construction to provide support and stability.

Its main function is to distribute the loads of the roof towards supports efficiently and safely, allowing the structure to be resistant and light at the same time.

Frame

Frames are one of the basic components of the structure and consist of 2 uprights, their corresponding diagonal braces, upright bases and fixing elements.

AR Racking has a wide range of frames to meet the storage needs of any company, from lighter loads to heavier loads.

Bases and anchor bolts

In a clad-rack warehouse, the bases and “anchor bolts” refer to key elements for the stability and safety of the structure.

The correct installation of both elements is essential to ensure that the load is distributed evenly to the slab and guarantee structural stability.

Roof purlins

Roof purlins are one of the essential elements of clad-rack warehouses. They are located on the top of the trusses and allow the enclosure panels to be fixed to the structure.

Their function is to join the trusses and boost the strength and stability of the structure, ensuring that the roof is capable of withstanding the different forces and loads to which it may be exposed.

Other elements and accessories of clad-rack warehouses

Safety fence

They are barriers designed to delimit and protect specific areas within a clad-rack warehouse.

These barriers are designed to ensure the safety of people, protect the integrity of the structure and control access to restricted areas.

Stairs for access to floors

The access stairs to the floors are structures designed to allow the safe and efficient movement of personnel between the different levels of the warehouse.

Back stops

It is a safety or protection element that is used in various contexts to prevent or avoid risks or damage and increase warehouse safety and stability.

Top hat sections

Top hat sections can adjust the height of the levels to accommodate goods of different sizes and optimise the use of available space in a warehouse. This type of design allows for greater flexibility in the organisation and storage of products.

Sprinkler support

It is the structure designed to hold and position fire sprinklers in all types of buildings and structures effectively.

The clad-rack warehouses comply with the most demanding European safety standards, and also have the AR Racking quality and innovation guarantee.

5-year quality guarantee

The reliability of our Clad Rack Warehouses solutions means we are able to offer 5-year quality guarantees against all types of manufacturing or hidden defects in the components of the main structure of our racking solutions.

Pioneering component traceability system

Since 2016, our Selective pallet racking components have included a component traceability system.

With this system, the various above-mentioned elements have an identifying mark, which means being able to trace and document each component from origin without needing to have the package label, and therefore, knowing which piece it is, its design and what raw material has been used in its manufacture.

100% automated production

Our industrial racking production process is fully automated: it incorporates state-of-the-art profiling machines with a continuous cutting process and laser measurement control, welding centres, painting and packaging processes, all automated, which guarantee the highest quality parameters.

Designs in R&D&I Centre

The structures of our Selective pallet racking systems are designed in our exclusive R&D&I technology centre and supported by the advanced engineering project development area, helping to provide a suitable response to the most demanding logistics requirements.

Tests at Research and Testing Laboratory

With the creation of our Research and Testing Laboratory in collaboration with the University of Mondragón, our technical area continuously tests and analyses products and materials to improve our Selective pallet racking systems; it simulates, calculates and researches (with specialist software) the efficacy of the geometries, and makes full structural calculations on the behaviour of the systems already installed in different situations.

Clad Rack Warehouses quality certificates:

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Marcado CE EN 1090-1

- Welding certificate: UNE EN ISO 3834-2: 2006

- Galvanized steel corrosion resistance certificate: UNE EN ISO 14713-1

- Galvanized steel reaction to fire: EN 13501-1: 2007