Live Storage for Picking

The Live Storage System for picking, also called Carton Flow Rack (AR Carton Flow), permits high density storage of cartons and light products, leading to savings in space and improved stock turnover control.

The Carton Live Storage system has a slight incline on the platforms that enables the sliding of the products that enter the racking from one end to the other, thus reducing distances travelled in the warehouse and saving operations time, so it is perfectly adapted to warehouses with a large volume of manual picking operations.

These gravity racking systems are often used in warehouses to make the order preparation of small items or light cartons more efficient.

They are also designed to operate according to the FIFO warehouse management method, ensuring excellent product rotation and eliminating possible interferences, by having two clearly separated areas for loading and unloading, which is why it is an unbeatable storage system for when we need to manage many products with a high level of rotation.

Live Storage for Picking

Carton Live Storage is a gravity system with slightly inclined platforms or roller beds where the goods are placed at the higher end and move to the other through gravity, with those goods previously stored on the racking being the first ones to exit at the opposite end. This operation allows FIFO (First in, First out) stock management.

When removing the first carton, the others move automatically towards the operator’s position, which means we can store a large number of references in the same bay.

This storage system is designed for companies and organisations with a high level of picking, increasing the number of lines and agility in the order preparation process, and reducing handling costs and movements of operators inside the warehouse.

The rails can be easily adapted transversely to accommodate different unit loads, making it a very versatile system for picking.

Live Storage for picking advantages and features:

These are the main advantages of the carton live storage system:

- Exploitation and optimisation of available space in the warehouse. High-density storage system, i.e., the same space but with more storage capacity.

- Perfect product rotation: When implementing the FIFO (First in, First out) system, the first unit load in is the first one out.

- With no passageway obstructions, either in replenishment or order preparation tasks, because the unit loads are placed and removed on different aisles, as the loading and unloading aisles are separated.

- Compatible and combinable with other AR Racking storage systems.

- It allows for the possibility of adding aisles with height levels and installing adjustable pallet racking on the upper levels.

- Adaptable to different sizes and shapes of cartons and light loads. The incline and the distances between pulley rails can also be modified, while the height and angle of inclination is adjustable too.

- Simple and quick installation. The installation does not require subsequent maintenance either.

- It increases the profitability of the warehouse, reducing operator handling and movement times due to the higher number of references at the front of the racking, meaning shorter distances.

- Quick and simple removal. The manual handling and removal time of unit loads is reduced due to the good location of the products.

- Possibility of simply installing order preparation systems with WMS (Pick to light) integrated in the actual storage solution.

Main applications of Live Storage for Picking Solution

This storage system is designed for companies that have a very high volume of picking and high quantity of homogeneous products, and ensures perfect product rotation and warehouse optimisation.

- These types of solutions are implemented in a very wide variety of sectors: from warehouses for consumer goods, such as pharmaceutical and cosmetics products, to computer products, automotive components, etc.

- Carton Live Storage is popular in consumer product sectors such as the food sector due to the importance of expiry dates.

- It is a very commonly used storage system in warehouses and distribution centres for components for the automotive sector.

- They are suitable storage systems for storing small or light items of any size, mainly for picking or order preparation of small loads.

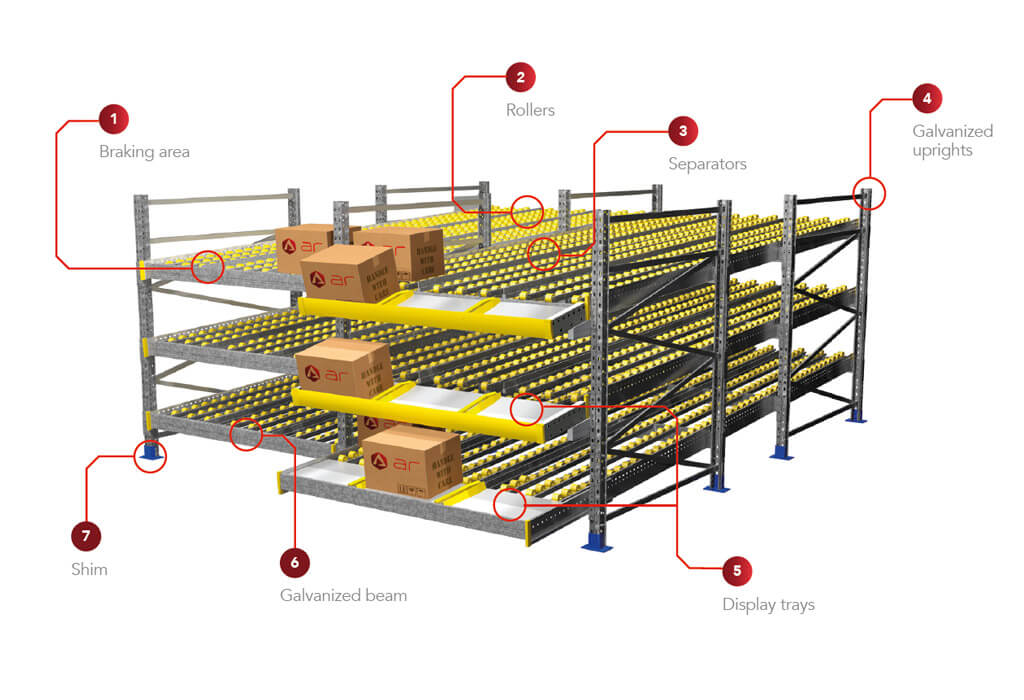

Live Storage for Picking Racking Components and Accesories:

The Carton Flow Rack system is applicable to the range of storage needs designed for the picking operations. It therefore has a base frame consisting of the entry and exit profiles, side profiles and guide rails.

Live Storage for Picking System also has a wide variety of variable or optional elements that allow it to adapt to the specific needs of each installation or sector such as the display trays, straight platforms, separation, braking systems, etc.

Frame elements in Live Storage for Picking System

Frame

The main function of the frame is to support the load levels of a bay, consisting of two vertical uprights, plus the diagonal profiles, base supports and corresponding accessories.

It consists of two beams joined together by a series of side safety pins.

Shim

The shim is a component located under the frame support in direct contact with the floor if it is uneven, to ensure the correct levelling of the entire structure.

This guarantees that the structure is well balanced and levelled, which is essential for safe operation.

Galvanised upright

The upright is the main component of the frame, and is galvanised, which provides support and stability to the structure.

It is a component that forms the vertical structure and helps withstand the load that it supports. Its design will depend on the load capacity that the racking has to support.

Beams for Live Storage for Picking System

Galvanised beam

The beams are metal components attached directly to the frames. They are the horizontal elements that connect to the uprights and act as support for the racking pallets on which the stored products are placed.

They are manufactured in different lengths and widths according to the load capacity required and are adjusted between the uprights to define the horizontal distance between the racks and trays. They are also responsible for distributing the weight of the loads evenly.

Specific elements of Live Storage for Picking Solution

Braking area

The braking area may consist of different types of devices, such as special wheels or rollers that provide resistance to product movement. They can also include specific speed control mechanisms.

This component is placed at the end of the rail and is used for product braking and control, preventing its impact against the outflow profile.

Reducing the speed of the products before the presentation area facilitates the picking process and minimises the risk of accidents or damage to the products.

Rails

Metal components that have in their interior a set of wheels, pulley wheels or rollers that allow the sliding of the load.

Rollers

This is one of the most important components of the carton live storage system. Its main function is to slide the load placed on the racking thanks to a slight incline in its structure.

This component may also consist of wheels, fulfilling the same function.

Dividers

They are metal components used to divide and organise the products into different channels in the racking.

These dividers are essential to maintain the order and facilitate the identification and removal of products during the picking process. They also serve to help the operator to place the load on the racking.

Presentation trays

These are tray-shaped flat surfaces located at the front of the inclined channels. These trays play an important role in the order preparation process, as they provide an easy to access and visible space for the products that are ready to be selected.

The presentation trays also act as a waiting area for the products that are at the front of the channels.

Once an item has been removed from the presentation tray, the goods behind it will occupy its place, thus maintaining a continuous flow of unit loads ready to be selected.

These trays can be tilted to facilitate the removal of the products that are stored inside a carton.

Possibility of combination with other systems

One of the great advantages of Live Storage for picking is its simple adaptation in combination with other pallet storage systems.

The installation at lower levels of Carton flow rack systems enables the installation of other systems at higher levels, as shown below:

- PUSH-BACK RACKING

- ADJUSTABLE PALLET RACKING

- FIFO LIVE PALLET RACKING (First in, First out)

Live Storage for Picking systems comply with the strictest European safety standards, and also come with AR Racking’s quality and innovation guarantee.

5-year quality guarantee

The confidence in our Carton Live Storage systems means we are able to offer 5-year quality guarantees against all types of manufacturing or hidden defects in the main structural components.

Component traceability system

Since 2016, the main components of our racking systems have included a component traceability system.

With this system, the different components have an identifying marker, which means knowing and having documented each piece from source without needing to have the package label and, therefore, knowing the exact component, how it was designed or what raw material was used in its manufacture.

Fully automated manufacture

The production process of our industrial racking systems is fully automated: it incorporates latest generation profiling machines with continuous cutting process and laser measurement control, welding centres, painting and packaging processes, all fully automated, guaranteeing the highest quality parameters.

Designs in the R&D&I Centre

Our Carton Live Storage systems are designed in our technology centre dedicated exclusively to R&D&I activities, as well as with the advanced engineering projects development area, which allows us to respond appropriately to more demanding logistical requirements.

Tests at Research and Testing Laboratory

With the creation of our Research and Testing Laboratory, together with the University of Mondragón, our technical area continuously tests and analyses products and materials to optimise our industrial racking.

It simulates, calculates and researches (with specialised software) the efficiency of the geometries, and makes full structural calculations on the behaviour of systems already installed in different situations.

Quality certificates in live storage for picking system

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Resistance of galvanised steel certificate: UNE-EN ISO 14713-1

- Reaction to fire of galvanised steel: EN 13501-1: 2007

References

With over 26,000 storage projects completed in more than 60 countries, we are leaders in industrial racking solutions. We are proud to have collaborated in the optimisation of warehouses with picking solutions for international companies from diverse sectors.

Some notable projects include: