The correct distribution and location of the goods greatly facilitates the logistics operations of a warehouse or distribution centre. It is of little or no use to equip an installation with the appropriate industrial storage system if the arrangement of the load hinders the work flow and/or could cause damage to the goods themselves or even cause an accident involving warehouse staff.

Monitoring the unit load is one of the many factors to consider when it comes to safety in warehouses.

Thus, the unit load is a homogeneous grouping of a set of products arranged on a support or platform that facilitates the handling and transfer of goods and that therefore acts as a logistical unit as such.

The unit load can be the product’s own packaging box, a container or a pallet, which is the main support in pallet racking systems as its name indicates, and not intended for picking or medium and/or light loads in cartons.

What is a pallet?

A pallet is a support or platform for boards to stack the load. They are rigid frames on which the goods are placed, distributed in a homogeneous way at height and on the pallet surface. The pallets, and consequently the load, will be transported from one side of the racking or the warehouse to the other by means of forklifts or pallet trucks.

Types of pallet

There are different kinds of pallets, depending on their size, their composition, etc. We list below the main existing pallets and their characteristics.

1) Pallets according to their dimensions:

Europallet:

It is a support whose measurements are 1200x800 mm. It is currently the most widespread in Europe. This type of pallet is regulated by EPAL (European Pallet Association) and as its website indicates, “around 500 million are currently in circulation”.

In addition, it is one of the types of pallets standardized by ISO (International Organization for Standardization). European industry and logistics therefore use the europallet as the main support to facilitate the flow of goods and their grouping in the transport and storage process.

The measurements of the europallet are determined by the width of the truck wagons, containers and trailers, which are usually 2400 mm, which allows them to be placed in a way that takes full advantage of the load space.

Main characteristics:

- Measurements: length 800 mm, with 1200 mm.

- Materials: 11 wooden boards, 9 blocks, 78 nails.

- Approximate weight: 25 kg.

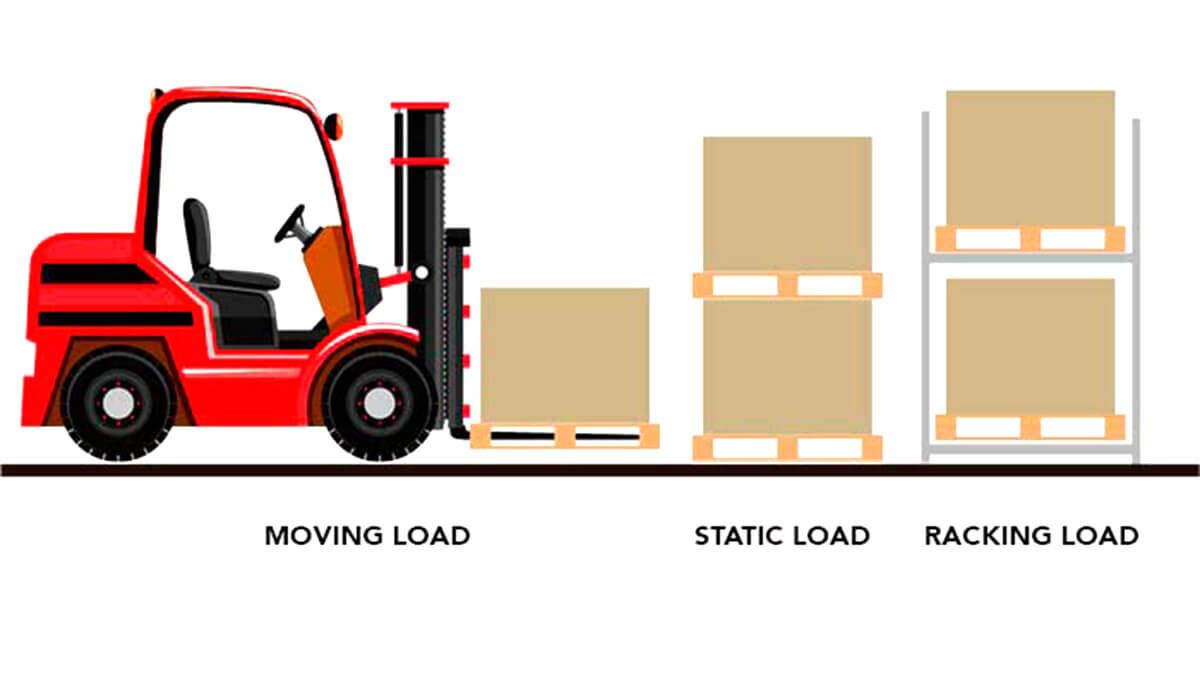

- Safe workload on the move: 1500 kg.

- Static load: when stacking loaded pallets on a solid and even surface, the lowest pallet should not exceed a load of more than 5500 kg.

- They contain various markings for identification, such as the licence number and the treatment method. However, the most visible is the acronym EPAL.

American pallet:

The dimensions of the American pallet are 1200x1000 mm and it is widely used in American and Japanese logistics. It is also called a universal pallet or isopallet.

Main characteristics:

- Measurements: length 1000 mm, width 1200 mm.

- Approximate weight: 25 kg.

- Safe workload on the move: 1500 kg

- Static load: do not exceed 6000 kg on a smooth, solid and safe surface.

Other pallet measurements:

The ISO organisation identifies a further 4 standardised measurements apart from those indicated for the europallet and American pallet which are as follows: 1016x1219mm, 1165x1165mm, 1067x1067mm and 1100x1100mm. These types of pallets are used far less widely than the europallet or American pallet.

2) Pallets according to the number of entry points:

Entry points refer to the number of sides where the forklift introduces the fork to be able to move the load.

- 4 entry points: the forklift or mechanical equipment to transport the pallet can access the pallet on any side along either the length or width.

- 2 entry points: the pallet can only be accessed on 2 sides opposite to each other. These pallets have less mobility than those with the 4 entry points because they are less accessible.

3) Pallets according to their manufacturing material:

Wooden pallet:

Wooden pallets are the most demanded, having a market share of around 90% or 95%.

Advantages:

These are pallets with competitive prices in terms of their resistance, reliability and ease of repair, which lengthens their life cycle. Another advantage is their ease of recycling.

Disadvantages:

Damage to the structure of the pallet if the wood has been severely knocked and difficulty with its cleaning and disinfection.

* Wooden pallets, regardless of their measurements, are subject to ISPM 15 regulations, which governs how wood packaging material, including the pallets, must be treated in international trade. ISPM 15 requires that pallets be manufactured using debarked wood and that phytosanitary treatment is applied to prevent the presence and proliferation of wood-related pests. Pallets that comply with this regulation contain the corresponding identification plate or labelling.

Plastic pallet:

This is an option that has gradually been gaining ground on wood pallets.

Advantages:

Easier to clean and disinfect than wooden pallets. They are lighter because they weigh less and are even more durable than wooden ones because any knocks cause less impact to the pallet. They are also 100% recyclable.

Disadvantages:

They are more susceptible to deformation under excessive loads and are more expensive than wood. It is also important to know what exact material they are made of because resistance and durability will vary significantly depending on the type of plastic. Also, if the pallet suffers any substantial damage, the component must be replaced without the possibility of repair.

Metal pallet:

The most resistant and also the heaviest, usually of steel or aluminium. Mostly used in the metal industry.

Advantages:

Metal pallets are easy to clean and disinfect and also have a long useful life due to their strength and impact resistance. They also support very heavy loads.

Disadvantages:

Their weight is greater than pallets made with other materials which increases the cost of transport.

Cardboard pallet:

Mainly designed for light loads.

Advantages:

They are disposable and recyclable, inexpensive and easy to handle due to their lightness. They are also characterised by their low weight. They are the cheapest types of pallets.

Disadvantages:

Very short life cycle because they only have a single use.

4) Other types of pallets:

- Reversible pallet: these are those pallets that enable loading tasks both from the top and from the bottom, with both sides being identical and homogeneous.

- Closed pallet: also called flat pallets, they only have one side that can be loaded and are closed by a slat that covers one of the backs.

- Wing pallet: they have projections on two or four of their sides to facilitate the use of fastening systems.

Recommendations for loading the goods on pallets

This is a more important manoeuvre than it may seem, since the correct handling of the pallet and the loading of the goods on said support will largely depend on the correct condition of the products:

- Do not leave any gaps between the pallets to avoid unbalanced stacking.

- Place the pallets crosswise if they are to be transported by trucks or any other means of transport.

- The load must not exceed the dimensions of the pallet; if it does, shrink wrap the load.

- Know the height and weight of the load to know exactly how many pallets can be loaded on the means of transport or in the warehouse.

- The goods should ideally be placed in such a way that makes it more easier for the forklift to handle the pallet.