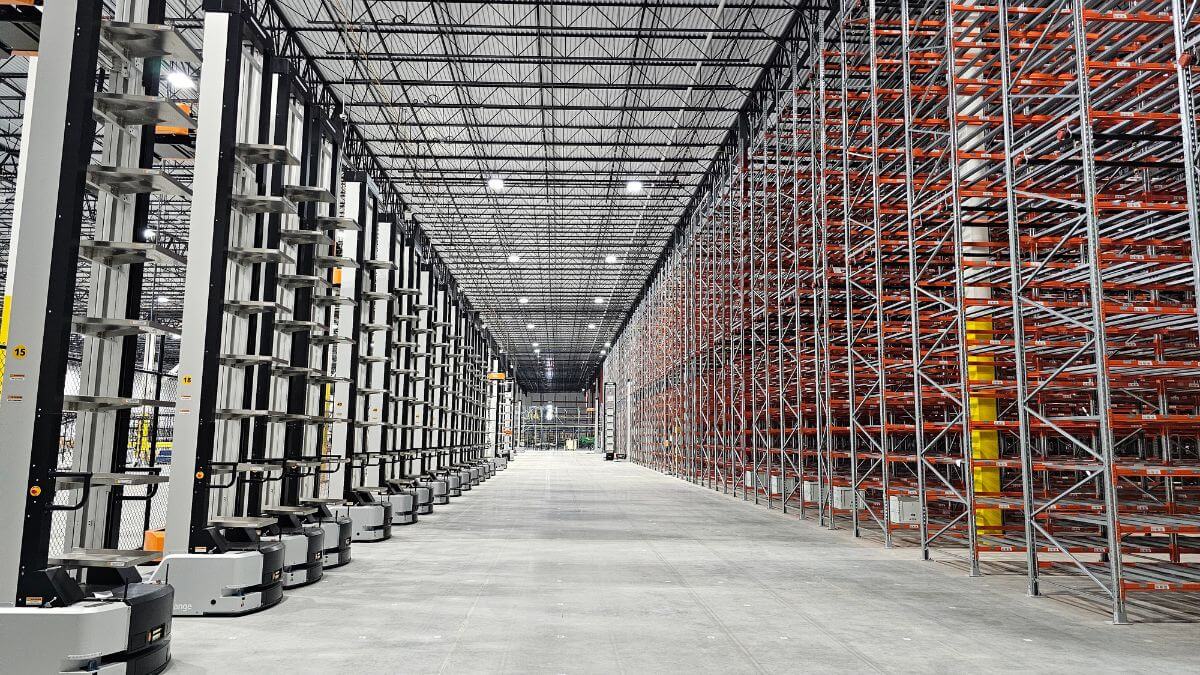

Compact storage systems are those which prioritise the optimisation of both surface space and space at height.

When choosing the solution that best adapts to a warehouse several factors must be considered, because not all industrial racking systems offer the same advantages or are valid for ensuring the maximum productivity of a warehouse.

The load volume, horizontal and vertical space of the surface, stock rotation or having direct access to pallet loading are aspects that must be considered before deciding on which storage system to implement.

Storage systems can be classified according to whether the load is for pallet racking or for picking, the level of automation or the management method.

Another major classification is that of the compact pallet storage systems, those in which maximum use of space is prioritised. This compaction of the storage space is normally achieved by reducing or eliminating the work aisles.

Advantages of compact storage systems

As mentioned, depending on the characteristics of the product to be stored, the management of the product itself and the peculiarities of the warehouse or logistics centre space, priority will be given to maximum use of the area and height of the warehouse, instead of immediate access to the unit loads, for example.

Compact storage systems are those that meet the above-mentioned characteristics. The main generic advantages they offer are as follows:

- Maximum optimisation of the space: when the surface area of the warehouse is small or the cost of extending it is high, compact pallet systems offer almost full use of the whole surface area.

- Orderly logistics management: load compaction requires exhaustive stock diligence, without room for more arbitrary stock controls and management.

- Close reference control: compact storage solutions are great for when there are multiple pallets for the same reference.

- Versatility: both LIFO management and the FIFO method can be operated within compact systems, depending on the type of industrial racking installed.

- Cold storage solutions: Compact storage systems are the ideal solution for cold storage due to their compaction, reduced volume to cool and the possibility of a controlled temperature distribution.

However, each one of the different compact storage systems has its own characteristics, logistical nuances and, therefore, specific advantages.

Types of compact storage systems

Although it is true that the main objective of compact systems is to maximise storage capacity, both at height and on the surface, it is also true that the different solutions based on industrial racking offer specific and distinct advantages.

What are the different compact racking systems we are talking about?

Drive in and Drive Through Compact Systems:

This is the compact system for the warehouse par excellence, and also the simplest of all of them. Compact racking is a high-density pallet storage system.

Functioning:

Full use of the space is made of due to its functioning. In this compact system for pallets, parallel aisles are generated inside the structure where forklifts circulate to load or unload the unit loads. In other words, loading and unloading lanes are created inside the racking.

Noteworthy characteristics:

- More than 80% optimisation of the space, taking advantage of surface and height.

- Ideal for uniform loads, with a high number of pallets per reference.

- Low maintenance cost.

- Elimination of service aisles.

Types of compact racking:

Drive in Compact Pallet Racking (LIFO):

This is the most common compact racking system. It consists of a single access aisle for the forklift. It works according to the LIFO method, so the last load in is the first load out. Indicated for warehouses with a low rotation of stock, such as, for example, with non-perishable products where how long the stock is held for is not important. See functioning video.

Drive Through compact racking (FIFO):

The flow of goods is controlled by the FIFO method, where the first load in is the first load out, therefore requiring two access aisles, situated at each end of the racking. It is indicated for high rotation of goods. It therefore adapts perfectly to the type of storage that perishable products may need.

Live Pallet Racking

As with Drive in and Drive through racking, this solution also looks to increase the use of space. It is a high-density system that consists of a compact structure which, by means of roller conveyors and a slight incline, allows the sliding of pallet loads on them.

Functioning:

The pallets are stored on rollers installed on the metal structure, with the load sliding from the entry to the exit point thanks to the incline of the rail. The LIFO system is used, so the first load in is the first load out. Loading takes place at one end of the racking and unloading at the other. See video.

Noteworthy characteristics:

- Better use of the space: more storage positions in the same space.

- Enables high product rotation.

- Strict management of FIFO, and therefore total stock control.

- Faster loading and unloading time, as well as rapid and simple extraction.

- Flexibility in obtaining pallets.

- Adaptable to any space, weight and size of the goods to be stored.

- Lane depth.

- Each level can store a different reference.

- It is a high-density solution that adapts perfectly to the storage of perishable products or those products that can end up obsolete. What’s more, live pallet racking is an ideal option for areas of transition of the warehouse or close to the order area.

Push-back Racking

This is a live storage system for storing pallets which, in contrast to FIFO live storage systems, has a single loading and unloading point, and the unit loads are stored by pushing the previous loads towards the back of the racking.

Functioning:

The pallets of each level are placed on the corresponding work aisle and the load slides on rails mounted on the beams, which have a slight incline, with the front part where the forklift works having the least incline. It works according to the LIFO method.

When the first unit is unloaded, subsequent unit loads move along the sloping rail by the force of gravity.

For loading, the forklift pushes the unit loads already stored towards the back, creating space for the new pallet loads. See video.

Noteworthy characteristics:

- Minimum operating costs due to excellent space optimisation.

- Immediate and simple inflow/outflow.

- Allows one reference for each work aisle and each level of the racking.

- Optimal solution for high and medium stock rotation.

Types of push-back racking:

Push-back with shuttles:

Each pallet, except the last one, is deposited on a shuttle, which moves on rails with a slight incline.

Push-back with rollers:

The load is moved by means of roller beds fixed to the structure with a slight incline.

Push-back live storage racking is the perfect solution for non-perishable homogeneous products or products with a long expiry date.

AR Shuttle racking system for pallets

The AR Shuttle racking system is a compact semi-automated storage system for pallets that uses motorised pallet shuttles that move through the interior of the racking autonomously to transport goods.

Functioning:

It allows the automatic loading and retrieval of pallets continuously by remote control. The shuttle is the pallet shuttle that allows the load to be moved inside the aisles of the racking. The shuttle must be placed in the first position, where the truck will deposit the pallet load on the pallet shuttle so that this then places the pallet in its appropriate position in the racking. After completing the unloading, the shuttle returns to the start of the rail. The forklift will move the shuttle to the next work lane. See video.

Noteworthy characteristics:

- There is no lane depth limitation.

- Both the FIFO and LIFO management system can be used, although the latter is more common.

- As with other compact storage systems, work aisles are reduced and the available space is fully exploited.

- Optimum safety conditions for operators by reducing their involvement in loading and unloading manoeuvres.

- Very rigorous stock control as it enables automated stock control through sensors that count the stored pallets.

- Unlike other compact systems, the pallet shuttle solution gives the warehouse more flexibility.

- This system fits perfectly in a context in which there are a fewer number of references and more pallets per reference.

Types of solutions with pallet shuttle:

- Pallet shuttle (with forklifts):

This is the pallet shuttle in metal racking described above whose movement from one rail to another depends on a forklift. - Pallet shuttle in automated warehouse (with stacker crane):

In this case, forklifts are replaced by stacker cranes which will transport the pallet shuttle from one lane to another in the automated warehouse for pallets. This enables full automation of the warehouse. This solution is designed for when pallet movement is continuous and intense.

The suitability of compact systems compared to others with direct access to the pallets depends on the characteristics of the facility, the goods, the function of the warehouse and also the company’s investment possibilities.

For more information about compact storage systems or other industrial racking solutions, please don´t hesitate to contact us here.