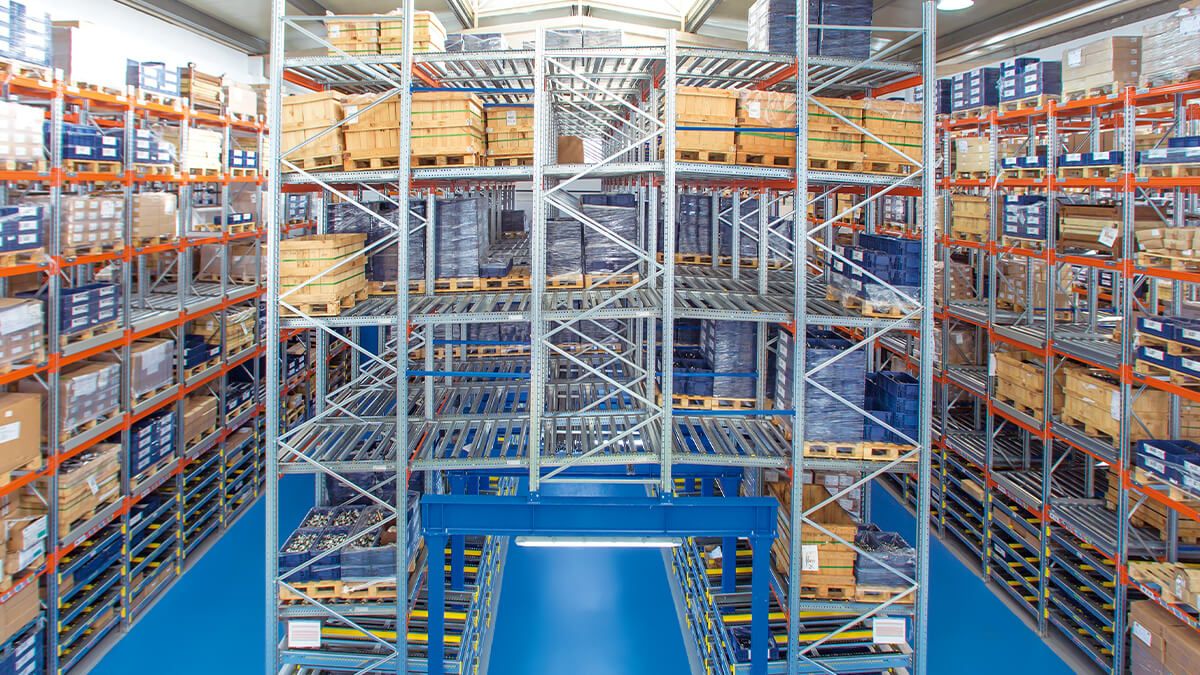

The importance of having good flooring in our warehouse is huge, as it is the base on which all our daily work is carried out and on which the industrial racking that stores the company’s goods will be fixed and installed. The material used to build this must therefore be appropriate for each type of job performed in each warehouse.

What is warehouse flooring?

These are the materials used to create industrial floors. All the activities in the warehouse are carried out on the flooring, so it is very important to carefully choose that which best adapts to each warehouse, as each one will support different loads, more or less wear, different products and chemicals that can damage it, etc.

It is also essential that the floor is safe for workers and the handling equipment at all times, and that it is of good quality so that it lasts long-term and so that warehouse investments can be amortised.

Importance of flooring in warehouse operations

Before building a warehouse, apart from correctly designing its layout, we need to choose the right flooring with which it will be complemented, as this is the base on which the rest of the installations will be built.

The warehouse flooring must support the tonnes of weight of racking and goods, as well as the continuous transit of machines and workers, so its quality is vital.

Another important aspect is the floor finish. This must be correctly levelled by a specific machine adapting it to the needs of each warehouse. But not all warehouses require the same flooring and materials.

Any small hole in the floor of our warehouse can cause an accident and reduce the safety of workers, goods and machinery. Therefore, apart from choosing high quality flooring, we will carry out periodic inspections of it.

Types of loads supported by the flooring

It is essential to consider the types of loads that warehouse flooring will support, with these divided into the following two categories:

Static loads

Static loads are distributed across the floor of the warehouse, concentrated on a specific surface area where the upright of the racking makes contact with the flooring. They are static loads, they do not move or change location, although their magnitude may vary slightly over time.

Dynamic loads

They are loads whose magnitude and location do vary over time. They are mainly the forklifts and other handling equipment that perform their daily operations in the warehouse aisles.

Essential characteristics of quality flooring

So that flooring correctly fulfils its function in the warehouse it must meet the following requirements:

Hygiene

A lot of dirt is normally accumulated in warehouses due to all the different processes carried out in them, but these materials provide excellent cleanliness as they are easy to clean and very hygienic.

Resistance

The outstanding characteristic of these materials is that they are incredibly resistant to any type of impact, temperature or chemical. So, we do not need to constantly worry about their condition.

Facilitate and simplify

Their design and simplicity provide favourable work space conditions, making the whole process simpler, such as sliding with the machinery or cleaning the surface. They also have non-slip and waterproof characteristics to avoid accidents.

Safety

They offer countless safety advantages. This is because the way in which they are established and how they are created mean they can be materials that withstand any disaster such as fire, humidity, floods, etc. This provides a great deal of confidence and protection for both warehouse employees and goods.

Adaptation and versatility

They adapt to any type of needs, regardless of whether they are spaces that need greater hygiene, or are exposed to strong chemicals or low and high temperatures.

Types of flooring

There is a wide range of flooring available for a warehouse. Over the years new more complex materials with better features have arisen that ensure warehouses have a perfect surface for the secure installation of storage systems with high load capacities.

Listed below are some of the most common floorings in a warehouse:

Epoxi flooring

This material is manufactured with an epoxy resin, which is a highly resistant material that prevents the creation of joints on the floor, helping to reduce accumulation of dirt and favouring easier cleaning. It is also of great strength and durability resulting in less long-term maintenance.

Its advantages include its flame-retardant property, as well as being non-slip and able to support the huge loads of industrial racking systems.

Polyurethane flooring

Polyurethane is characterised by being highly resistant to different temperatures. It is suitable for outside areas or cold stores, as it can support very high and low temperatures without getting damaged. Its main characteristics include resistance to abrasion and strong impacts, and being able to withstand solar and ultraviolet rays.

Polyurethane-cement flooring

This material which is a variant of polyurethane provides a great deal of firmness and durability to warehouse flooring as it is highly resistant to strong chemicals and thermal changes. This flooring is designed specifically for warehouses and distribution centres dedicated to the food, pharmaceutical and chemical sectors.

Flooring for clean rooms

This type of flooring is prepared to keep the spaces totally sanitised. It is used in spaces that require extreme cleanliness without any residue. It is normally used for warehouses with goods such as drugs, cosmetics, food products, etc. Its advantages are less contamination, resistance to temperature changes, its reasonable price and being very easy to clean.

Polished concrete flooring

This material is characterised by its aesthetics more than its resistance. It comes in different designs with eye-catching colours and its mirror effect adds an innovative touch. Another of its characteristics are its economical price, waterproof properties, resistance to chemical substances, and being easy to clean.