Each company’s logistics needs will determine the most suitable type of warehouse for them. According to the structure and atmospheric protection of the different types of warehouses, we can differentiate between covered warehouses and uncovered or outdoor warehouses.

In this post, we will focus on the latter, also known as open-air warehouses, looking at their different types, their special features and the characteristics that industrial racking or an outdoor storage system must fulfil.

Outdoor warehouses are not a common choice in companies because of their special characteristics, with most companies preferring an indoor warehouse.

Types of outdoor or open-air warehouses

As indicated, depending on the structure and atmospheric protection that the products to be stored require, we can differentiate between covered and uncovered or open-air warehouses.

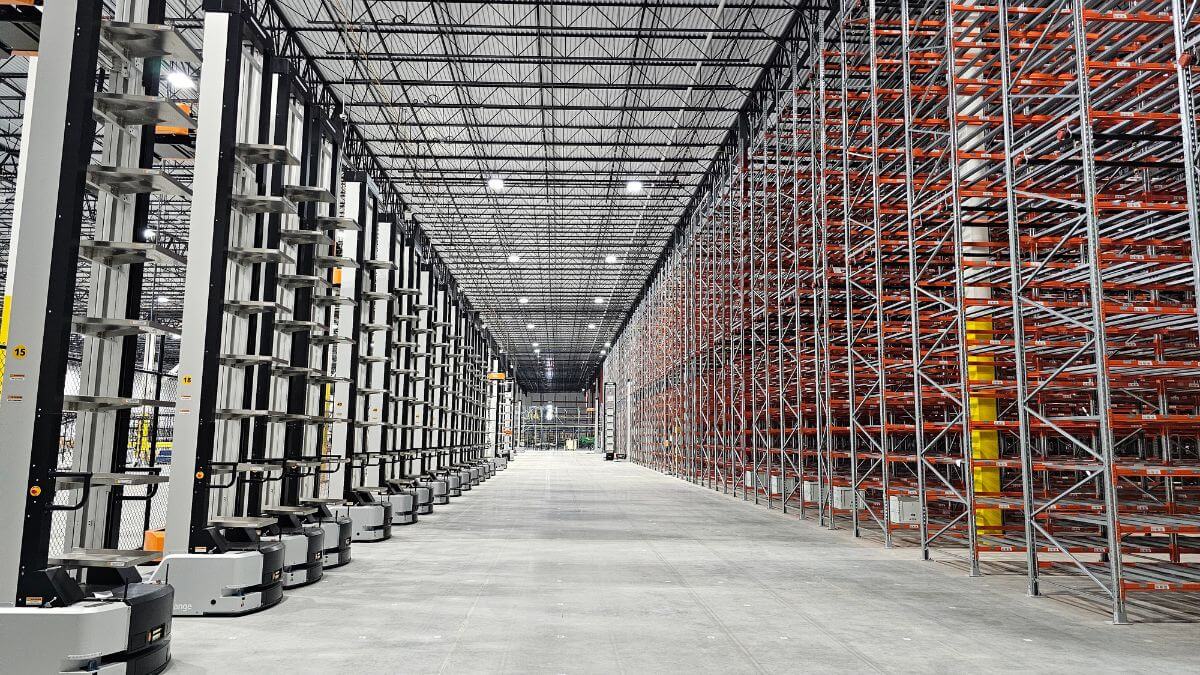

Without doubt, the most common warehouse or storage facility is the covered warehouse, due to the greater protection that it gives products, storage systems and machinery. The structure provides protection against external elements such as the cold, heat, rain, snow, solar radiation, etc.

However, sometimes the type of product to be stored by companies does not need this extra protection, so the outdoor storage option is chosen.

Open-air warehouses are generally more economical than covered warehouses as they do not have their own structure. Their space is normally delimited by fences or perimeter walls.

Materials stored in the open are usually those that do not suffer deterioration due to inclement weather, which means that the most common outdoor warehouses are for machines or vehicles and raw materials from the construction, metallurgy or timber sectors. Except in specific cases, more delicate products such as food and other perishable products should not be stored in an outdoor warehouse.

Among those considered, we can differentiate between 2 types, with the main difference being that one of them is a hybrid between the covered and uncovered warehouse:

Fully open and uncovered warehouse

In this case, the products and storage systems are fully outdoors, uncovered, with no type of roof or wall.

This is the typical warehouse for raw materials from the construction, metallurgy and timber sectors that do not deteriorate due to inclement weather conditions.

However, the stored products areoccasionally covered with tarps or plastic for greater protection, especially if they are going to spend long periods outdoors.

Partially open warehouse

This type of outdoor warehouse has some extra protection for the stored products; it may only be a roof or roof and walls, leaving one of its ends uncovered to continue to be considered an “open” warehouse.

These warehouses are designed with the idea of protecting the products, mainly from direct rain or snow, but the stored materials will continue to suffer temperature and humidity changes.

It is usually the type of open warehouse chosen for slightly more delicate products from the above sectors and for machinery and vehicles.

Considerations for outdoor industrial storage

Being a special type of storage, when designing open-air outdoor warehouses, the following points should be considered:

Analysis of environment and local environmental conditions

In new warehouse projects, each situation is different, particularly in open-air, outdoor warehouses.

As inclement weather conditions will directly affect the goods, a detailed analysis of the climate of the area where the warehouse is installed will be required: maximum and minimum temperatures during the year, humidity, wind, likelihood of rain and snow, seismic risk, etc.

For example, it may be possible for a specific product to be stored outdoors in a country with a warm climate, but it would need to be stored indoors in countries with extremely low temperatures.

Cleaning, lighting and signage

Being an outdoor warehouse, more dirt and waste will be generated on both the floor and goods than indoors. It is therefore very important that the premises are cleaned frequently and thoroughly.

Consideration also needs to be given to whether operations in this outdoor warehouse are going to be carried out only during the day or also at night, to provide the right lighting system for the facility, without any poor or zero visibility areas that greatly reduce the safety of the warehouse.

In both cases, the signage in the warehouse must be clear, visible from a distance and made of rain resistant materials. The load warning notices must contain all the same regulatory information as an indoor warehouse.

Assess risk and difficulty of theft of goods

Having less protection and privacy than indoor warehouses, it needs to be evaluated whether the product to be stored is of high value, and whether its weight and volume make it easy to transport.

Based on this assessment, it is then decided whether to increase the safety of the warehouse exterior with more fences or walls, surveillance systems, etc.

Corrosion resistant industrial racking and environmental conditions

Without doubt, one of the keys for the correct operation of an open warehouse is the choice of the industrial racking to store the product stock.

In outdoor storage, the racking will be subject to a far more extreme level of corrosion and environmental conditions than indoors, so the storage system must be prepared for this.

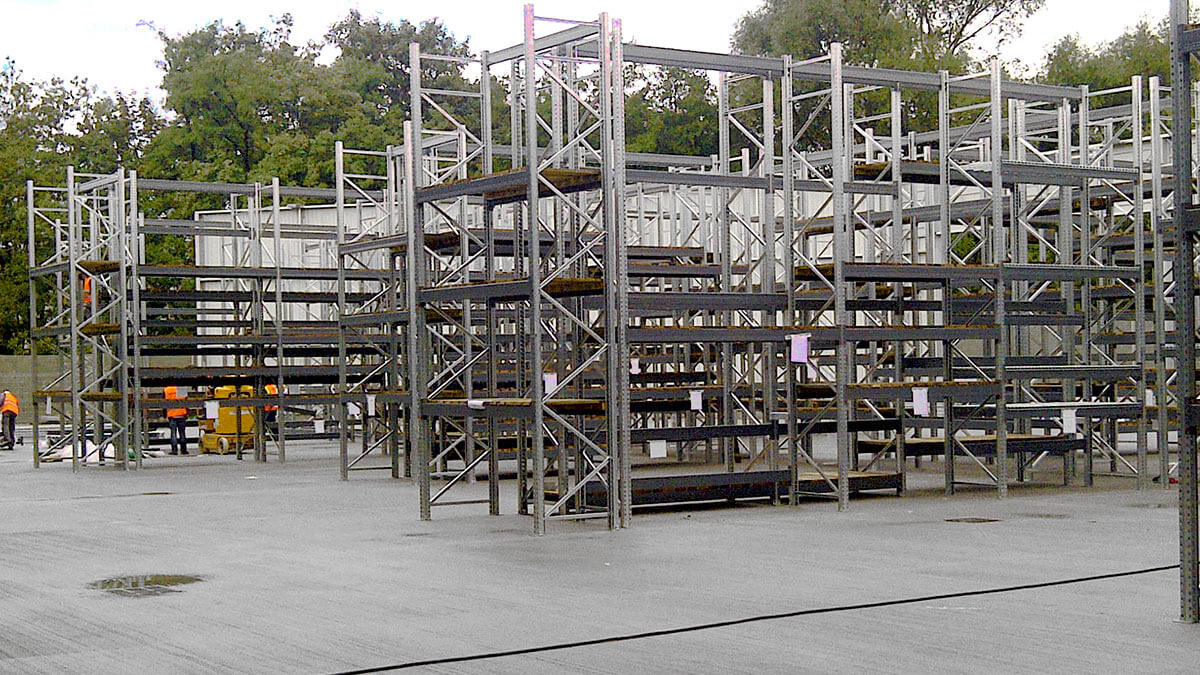

The best solution for these types of warehouses is galvanised racking, with high resistance to corrosion and temperature and humidity changes.

Characteristics that outdoor racking must meet

As indicated, the most recommended industrial racking for an uncovered outdoor warehouse is galvanised racking, particularly hot dip galvanised.

In the hot dip galvanised process, the parts that make up the racking structure are immersed in molten zinc to create a protective outer layer of zinc, which gives them greater strength and durability.

Immersion is done with a fully manufactured part so the part is fully coated and protected.

Other types of galvanised racking include pre-galvanised with less resistance to corrosion than the former, since the immersion in zinc is not done with the manufactured part, but rather on the steel spool which is the raw material of the racking. Take a look at the post where we explain how the racking is manufactured.

There are also protective paint systems for outdoor steel structures, which can be useful in less extreme conditions. The initial analysis of the project will define which is the most appropriate solution in each case.

Typical storage systems in outdoor warehouses

Of all the types of industrial racking solutions, generally the most common in outdoor warehouses are adjustable pallet racking systems, and also cantilever racking for long loads.

Outdoor warehouses do not usually have as many space constraints as indoor warehouses, so compact storage systems are not normally chosen, opting for adjustable pallet racking instead.

Adjustable pallet racking is a logistics solution adaptable to different size unit loads and to the type of forklifts, with direct access to all pallets.

It is a resistant and easy to assemble system with simple load level regulation; it adapts to any type of goods, both in weight and volume. Thanks to its galvanised racking, it is resistant to corrosion and adverse weather conditions.

Also, Cantilever Racking is quite often installed outdoors, being especially designed for storing long loads such as metal, wood or plastic tubes, profiles, plates and boards.

When Cantilever Racking is installed in an outdoor warehouse, a covered area at the top is normally added to give the goods more protection.

If you are looking for the right storage system for an outdoor warehouse, contact our team here, who will be happy to provide you advice.