Packaging is a key element in protecting warehouse goods; its main function is to secure and group together the stored products.

Below we look at the different types of packaging, their characteristics and storage differences.

Packaging concept and functions in a warehouse

The concept of packaging refers to the elements that protect and bundle together goods for their transport, storage and handling.

During supply chain processes, products are exposed to a series of potential risks that packaging must minimise.

Risks may be due to environmental conditions (extreme temperatures or humidity), handling errors (crashes, scratches, crushing, etc.), storage deterioration (expiry, erosion, corrosion, etc.), or others such as theft and robbery.

These risks can vary significantly depending on the type of load stored, especially in the case of the storage of chemicals.

The main storage functions in the supply chain can therefore be summarised as follows:

- Protect the goods in all phases of the supply chain

- Facilitate the handling of products with a correct grouping

- Communicate the characteristics of the goods to ensure their correct handling

- Occasionally, particularly in e-commerce companies, packaging also serves the function of communicating to and building the loyalty of the end customer, promoting the company’s brand image.

Type of packaging: primary, secondary and tertiary packaging

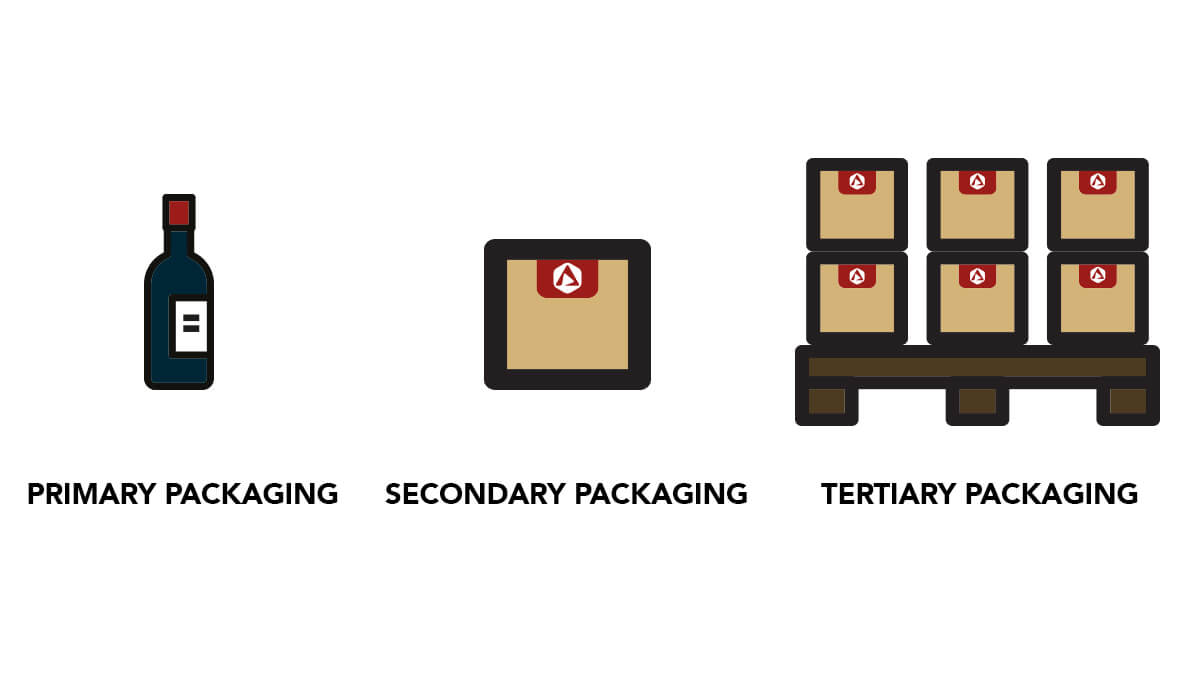

Types of packaging are mainly organised by the place each one occupies in the different protection layers for the product.

Primary packaging

Primary packaging is the type of packaging that is in direct contact with the products. Its main purpose is to protect them and maintain their ideal characteristics. The primary packaging of a product is the first material or layer wrapped around it and the one that defines its smallest unit of sale.

Apart from keeping the product in good condition, it is important that the primary packaging is eye-catching and appealing, as it will be the first image that the end customer receives when coming into contact with the product. This is particularly important in consumer or online sales products.

The functions of primary packaging are to separate, protect, secure, communicate characteristics and expiry and, in some cases, attract attention and build loyalty.

It is packaging of little relevance or visibility in the day-to-day operations of the warehouse, since it will be covered and grouped together by secondary and tertiary packaging.

By way of example, the following are considered primary packaging for goods:

- Milk cartons

- Beer cans

- Plastic bottles for detergent

- Sacks for packaging concrete

- Cardboard boxes for furniture

Secondary packaging

The purpose of secondary packaging is to create unit loads grouping various types of primary packaging, to make storage, transport and handling easier.

Generally, this type of packaging adds reinforcement to bundle together and secure the individual units of sale. However, sometimes consumer products are also marketed grouped together so they must be communicative and eye-catching.

Generally, secondary packaging is presented as cardboard boxes or other materials of different sizes and thicknesses, but also as plastic film.

Some examples for consumer products are the cardboard box in which bottles of beer are packed or the plastic film for wrapping water bottles together.

Tertiary packaging

Tertiary packaging will in general be the outer layer, the final and largest piece of packaging, which will also be stored and handled inside the warehouse.

Naturally, tertiary packaging consists of groupings of products in primary and secondary packaging.

The most common type of tertiary packaging is pallets of various materials, rigid cardboard boxes, containers or any other items that create a unit load for the simple transport and storage of the goods.

In tertiary packaging, the compacting of goods and the stability and resistance of the unit load in order to be stored on industrial racking in complete safety and fully optimising the available space in the warehouse will be key.

Therefore, taking for example wine as a product, the primary packaging would be the bottle, the secondary packaging the cardboard box in which the bottles are packed, and the tertiary packaging the pallet that groups various wine boxes together.

How do we determine the packaging for each product?

The choice of suitable packaging for a specific product is a decision that as explained affects all phases of the supply chain and end customer satisfaction.

When deciding on one type of packaging or another, the following variables need to be considered:

- One of the priorities must be cost optimisation; the direct cost of packaging must not affect the profitability of the product, and the most efficient packaging will be that which secures and protects the product with the lowest resource cost.

- The packaging chosen must help to reduce storage, transport and handling times in all phases of the supply chain.

- The type of product will clearly define the type of packaging. It will therefore be necessary to consider whether the goods are perishable or not, whether it is a liquid, solid or even gaseous product, and its weight and size.

- Chemicals or products with hazardous characteristics must have a special packaging that secures them. Further information on the storage of chemicals.

- The growing global concern for waste reduction in packaging processes is a matter that requires large companies to continuously adapt, with specific environmental plans to make packaging more sustainable.