An industrial racking frame is the main vertical structure that supports and provides load capacity to the racking system. Its correct design and assembly process are key to the safety and efficiency of the storage system.

In the logistics and warehousing field, industrial racking is an essential solution for organising and optimising storage space for warehouses, distribution centres and retail outlets.

In this article, we will look at how to correctly assemble a frame for an AR Racking industrial racking system.

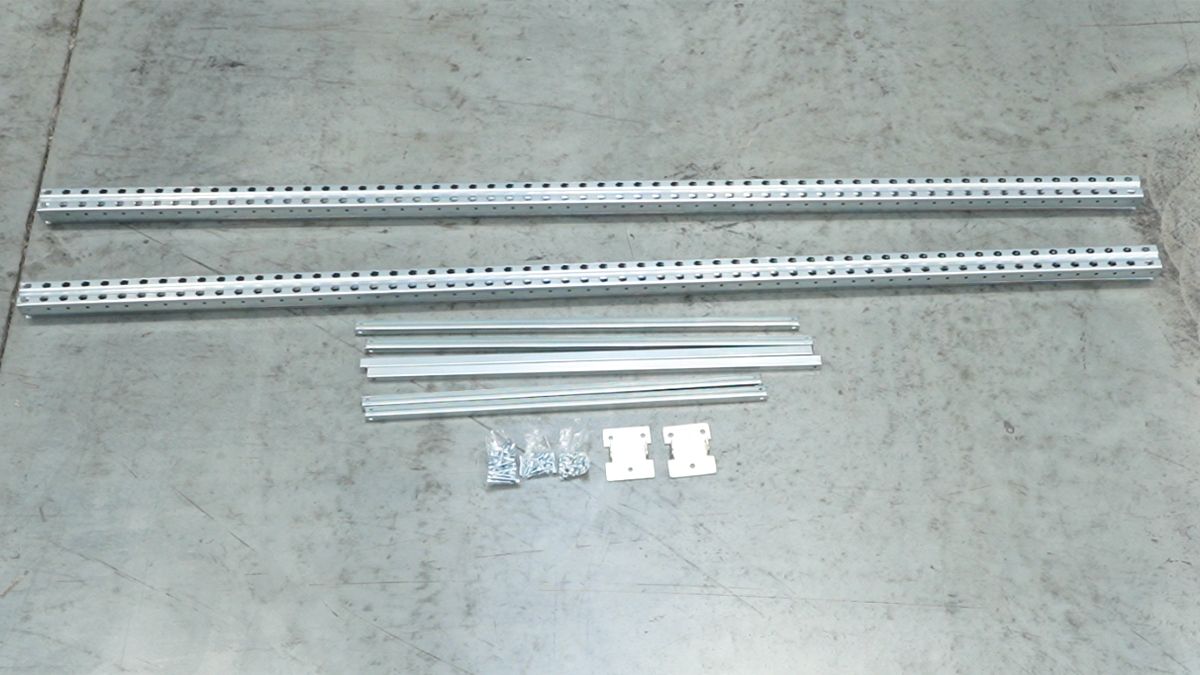

Necessary components for assembling a frame

To successfully assemble a frame, we will need the following components, which will form part of the structure of the frame:

Two uprights

The uprights are the main components in the structure of the frame and support the entire racking unit. The uprights give the structure its backbone and are responsible for keeping it vertical and stable.

The uprights also distribute the weight of the objects stored on the racking unit, ensuring that the load is supported evenly and that there are no excessive stress points that could compromise the stability of the structure.

Depending on the load to be stored in AR Racking we manufacture the uprights in different lengths and sections according to the customer’s needs and the structural requirements.

Finally, these components act as connection points for other parts of the frame, such as the horizontal and diagonal profiles. They enable the attachment of these parts, contributing to the overall rigidity and strength of the racking.

Diagonal and horizontal profiles

The diagonal and horizontal profiles are key elements in the structure of a frame. They are the parts that connect the uprights, forming the basic structure. These components perform specific functions to guarantee the stability and strength of the racking.

The diagonal profiles give the frame structural strength by connecting the uprights to one another at a diagonal angle. This helps to distribute the forces and loads more uniformly, strengthening the integrity of the entire racking unit. Likewise, by forming an X-shaped or lattice pattern between the uprights, the diagonal profiles increase the lateral stability of the frame. This avoids unwanted lateral movement, especially when products are loaded and unloaded on and off the racking.

The horizontal profiles are placed horizontally between the uprights to create racks on which the products are placed. They distribute the weight uniformly along the racking, ensuring that each level can support the designated load efficiently. Apart from serving as racks, the horizontal profiles strengthen the structure of the frame by providing additional support and stability to the uprights. They help prevent the deflection or bending of the uprights under load, preserving the integrity of the racking.

Baseplates

In a frame, the baseplate fulfils an essential function to guarantee the stability and safety of the entire structure. Its main purpose is to provide a strong and secure support point for the uprights, which are the vertical pillars of the racking unit.

This component is placed in direct contact with the floor of the warehouse. This ensures that the uprights are supported on a stable and firm base, avoiding unwanted movements or wobbles that could compromise the integrity of the racking. Similarly, the baseplate, by being in contact with the floor, helps to uniformly distribute the load across the uprights and to the floor.

Nuts and bolts and other fixings

The nuts and bolts and different fixings perform several important functions that contribute to the stability, safety and durability of the structure. They are mainly used to join and secure the different components of the frame, such as the uprights, diagonal and horizontal profiles, and baseplates. This joining ensures that the structure remains strong and stable, avoiding unwanted movements that could damage the stability of the racking.

These elements also ensure that the structure is assembled securely and that the components do not come loose easily, thus reducing the risk of accidents.

Manual assembly of frame: Step-by-step

Having defined the necessary components for the assembly, we can begin the assembly process itself. Performed in this case by two workers, and with the help of two trestles to support the uprights conveniently for their handling, we begin the first step.

Joining the baseplates

Firstly, we place the baseplates at the base of each upright, ensuring that they are correctly aligned with the holes, and then we attach the nuts and bolts. Using a drill, we firmly secure the baseplates to ensure the stability and safety of the structure. These baseplates are the part of the frame that will be in direct contact with the warehouse floor, so it is vitally important to fix them correctly.

Placing the horizontal and vertical profiles

We must then turn both uprights, so that the holes face outwards, and the hollow face faces inwards. Next, we place the horizontal profiles, in their appropriate position, at the ends between the two uprights, followed by the diagonal profiles, in their designated positions, according to the design. The diagonal profiles are placed from the top of one upright to the bottom of the other, forming a lattice to give greater stability to the frame. To guarantee a more secure structure, it is advisable to measure and ensure that the components have been placed correctly.

Attaching the horizontal and vertical profiles to the upright

Firstly, manually place the nuts and bolts of the horizontal profiles, followed by the diagonal profiles, starting at the ends, working towards the centre of the structure. This part of the assembly process must be done with special care and attention to detail, as the joining of the uprights to the horizontal and diagonal profiles is mainly responsible for ensuring the stability and strength of the frame. And, therefore, also responsible for the stability of the industrial racking on which the frame is installed.

Checking the stability of the frame

Once we have ensured that all the components are joined and aligned in their proper place manually, we will then correctly secure them with the help of a drill, passing to what will then be the last step of the assembly process. After all the parts have been put together and fixed in place, all we need to do is to check the stability of the frame, adjusting any bolt if necessary, and our industrial racking will be perfectly assembled.

This article is for reference purposes only. Always remember to check the assembly instructions and user guide provided by the manufacturer for optimal operation and maintenance of your storage system. If you need more information, advice or would like to request a quote on industrial racking for your warehouse, simply visit our website, and our experts will advise you on the best storage solution.