In the realm of modern industrial logistics—where efficiency, compatibility, and standardisation are decisive elements—the American pallet stands as a key component in storage and transport operations. With dimensions that have been globally adopted across strategic sectors such as food, pharmaceuticals, automotive, and retail, this type of pallet not only facilitates the handling of goods but also directly influences the design of industrial racking systems, logistics flows, and space optimisation.

This article explores in depth the role of the American pallet as a structural element within the supply chain. We will examine its technical specifications, advantages over other formats, its impact on warehouse operational efficiency, and how AR Racking offers storage systems specifically designed to maximise its functionality in demanding environments.

Definition and standardised dimensions of the American pallet

The American pallet, also known as the GMA (Grocery Manufacturers Association) pallet, has become a key reference in industrial logistics in North America and in other regions where high-capacity storage configurations and operational flexibility are prioritised.

Its robust design, versatility, and compatibility with automated systems make it an essential tool for optimising the supply chain in sectors such as retail, food, and manufacturing.

Additionally, its structure allows four-way entry, greatly facilitating operations with forklifts and pallet jacks. This feature is particularly valued in high-turnover environments, where speed and efficiency in goods handling are critical.

The American pallet integrates seamlessly into standard industrial racking systems and is compatible with automated solutions such as AS/RS systems, conveyors, and Pallet Shuttle systems, ensuring smooth and safe handling even in highly automated facilities.

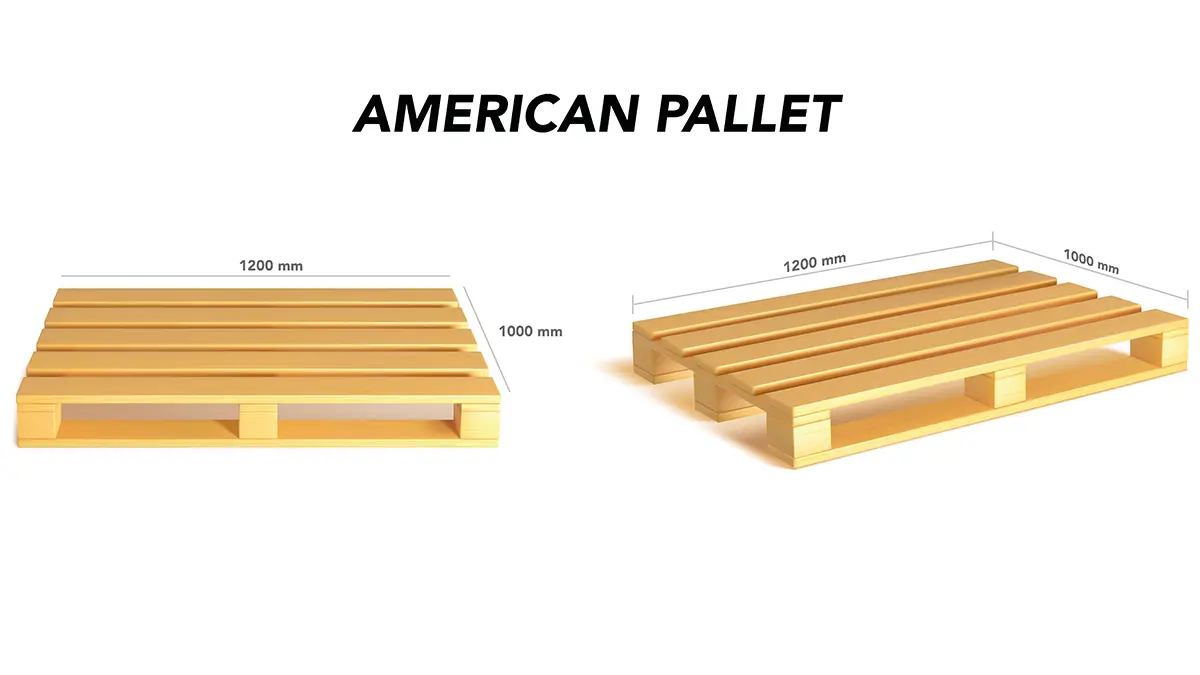

Dimensions of the American pallet

The American pallet is designed according to technical specifications that ensure standardisation and maximum interoperability within logistics systems. The most commonly accepted size is 1,200 mm in length by 1,000 mm in width, offering a slightly larger surface area than the European pallet (1,200 x 800 mm).

It typically has a height ranging between 144 mm and 160 mm, depending on its configuration and material.

These dimensions provide an optimal balance between volumetric capacity and compatibility with ISO containers, transport trucks, and conventional pallet racking. Furthermore, the proportions of the pallet make it suitable for both block stacking and racking systems of various depths.

Load capacity and weight

One of the key technical attributes of the American pallet is its load-bearing capacity. It is engineered to meet the high demands of modern logistics operations.

Under optimal conditions, a standard GMA pallet offers:

- Dynamic load capacity: up to 1,500 kg, allowing intensive transport and handling within warehouses.

- Static load capacity: exceeding 2,000 kg when stationary in storage systems.

- Weight of an empty pallet: varies depending on the manufacturing material, ranging from 15 to 22 kg for standard wooden versions. Plastic or metal variants exhibit slightly different weights based on design and required strength.

These load values make the American pallet particularly suitable for sectors handling high-density or large-volume goods, and ensure structural safety in high-bay storage configurations such as self-supporting warehouses.

Types and materials of the American pallet

The American pallet is available in various materials and structural variants, each optimised for specific uses and industrial environments.

Wooden Pallet

The most common and cost-effective type. Made primarily from pine, poplar, or other treated woods, it offers good mechanical resistance and is easy to repair. Ideal for high-turnover logistics flows and general applications.

Plastic Pallet

Designed for environments that require high standards of hygiene and quality, such as the food, pharmaceutical, or cosmetics industries. These pallets are moisture- and chemical-resistant and offer a long service life. Frequently used in automated processes and warehouse management systems (WMS) with high traceability requirements.

Metal Pallet

Mainly used in heavy industry and for storing hazardous goods. Offers extreme durability and superior load capacity. Suitable for demanding applications such as mobile racking systems or compact storage configurations.

Depending on operational needs, variations include:

- Single- or double-sided pallets.

- Pallets with open or closed top decks, depending on load type.

- Pallets with metal reinforcements for extreme loads or use in automation systems.

In any of its forms, the American pallet is a versatile and robust logistical solution, allowing for maximised efficiency in storage and transport processes.

Strategic and operational advantages of the American pallet

Choosing the right pallet is no minor decision: it directly impacts logistics costs, operational speed, and goods handling safety. The American pallet offers significant advantages in several key areas of industrial warehouse management.

From an operational standpoint, its larger surface area allows for better utilisation in sectors dealing with wider or bulkier products. This proves especially useful for homogeneously palletised loads such as large boxes, drums, or display packaging. Additionally, its sturdy structure and load capacity make it suitable for high-demand applications, including large-scale warehouses or reverse logistics operations.

From a strategic logistics perspective, the use of the American pallet enables:

- Reduced transport costs for full loads by optimising volume per pallet.

- Greater efficiency in mechanical handling, minimising picking and replenishment times.

- Improved compatibility with automated systems due to its symmetrical design and ability to withstand intensive repetitive use.

- Adaptability across multiple industries, simplifying supplier management and the design of multi-client warehouses.

Together, these operational advantages enhance the overall efficiency of the supply chain, reducing errors and improving traceability and quality control.

Technical specifications and compatibility requirements

The American pallet requires specific considerations in logistics design. Its compatibility with handling equipment and industrial racking depends on correct alignment of dimensions, load types, and storage systems.

Key technical aspects to consider include:

- Access type: American pallets allow four-way entry, but the type of block or centre skid can affect performance on conveyors or rollers.

- Beam spacing: racking systems must provide appropriate gaps to prevent pallet deformation under load.

- Material: wood, plastic, or metal. Each behaves differently regarding moisture, friction, wear, and regulatory requirements.

- Automation compatibility: in automated environments, pallets must maintain strict dimensional tolerances and good flatness.

- Ventilation and hygiene: in food or pharmaceutical sectors, certified plastic pallets are used to prevent contamination and enable washing.

These considerations are especially critical when designing dynamic racking, mobile base systems, or automated solutions like Shuttle or Miniload systems.

AR Racking solutions compatible with the American pallet

AR Racking designs and manufactures industrial storage systems precisely tailored for the use of American pallets, ensuring maximum efficiency, structural safety, and technical compatibility.

Our systems are configurable according to load type, rotation frequency, and operating environment. The most relevant solutions for American pallets include:

- Adjustable Pallet Racking: ideal for warehouses handling diverse palletised goods. Offers direct access and fast location.

- Drive In Racking: optimises space for large volumes of homogeneous products using 1,000 mm-wide pallets.

- Live Storage Pallet Racking (FIFO): operates using gravity flow for high turnover, ideal in consumption or intensive distribution logistics.

- Mobile Pallet Racking: smart solutions for space-constrained environments, allowing compact storage without sacrificing accessibility.

- Warehouse with stacker cranes for pallets: for high-density storage in automated settings with minimal manual intervention.

Each system is designed to meet quality standards and can be adapted to specific safety regulations or industries such as chemicals or food.

Recommendations for effective implementation

To maximise the benefits of the American pallet in the warehouse, an integrated approach is required—one that considers both the physical design and operational flows. Some best practices include:

- Ensuring dimensional compatibility between pallet, racking, and handling equipment.

- Using racking with anti-corrosion treatments when handling damp products or in refrigerated chambers.

- Integrating real-time stock management, ideally through WMS and LMS systems with location sensors.

- Designing aisles compatible with forklift manoeuvrability, particularly when handling 1,000 mm-wide pallets.

- Conducting periodic audits on pallet condition to avoid using deformed units that could compromise stability.

Detailed planning, coupled with expert technical advice, guarantees the efficiency and durability of the logistics infrastructure.

Common challenges and solutions when handling American pallets

Despite their numerous advantages, American pallets can pose specific challenges depending on the environment:

- Incompatibility with existing European racking: resolved by using adapters or redesigning load levels.

- Overloading on systems designed for European standards: requires recalculating load capacity and structural reinforcements.

- Damage from intensive handling: can be mitigated by using more durable plastic or metal pallets.

- Automation issues due to dimensional variability: best resolved by using certified pallets or automated inspection processes.

Overcoming these challenges involves accurate technical specification, rigorous maintenance, and collaboration with a specialised partner such as AR Racking.

American pallets and sustainable logistics

The use of standardised pallets such as the American pallet also contributes to the sustainability of logistics operations. Being largely reusable, repairable, and recyclable—especially in plastic or metal versions—they significantly reduce reliance on disposable resources.

Additionally, their compatibility with automated systems enhances energy efficiency, reduces manual handling, and optimises transport planning, thereby lowering carbon emissions. AR Racking integrates these principles into the design of sustainable warehouses, offering solutions that merge productivity with environmental responsibility.

Conclusion

The American pallet represents an essential technical standard in modern industrial logistics. Its robust design and compatibility with a wide range of storage systems make it an efficient and versatile solution. Implementing systems that optimise its use is key to achieving superior levels of productivity, safety, and sustainability.

Contact us and our specialised team will advise you on the design and configuration of industrial racking systems that maximise the performance of the American pallet in your logistics operations. We offer tailored solutions that ensure efficiency, regulatory compliance, and a solid foundation for the sustainable growth of your warehouse.