In the world of logistics and storage, pallets play a crucial role. They are the foundation upon which goods of all kinds are transported and stored. However, not all pallets are the same. There are different types of pallets, each with its own characteristics and advantages. In this article, we will explore the differences between two of the most common types of pallets: the European pallet and the American pallet. Knowing these differences is essential for optimizing logistics and storage in any company.

History and origin

- The European pallet, also known as the Europallet or EPAL, has its roots in Europe. It was developed in the 1960s by the European Pallet Association (EPAL) to standardize the transport and storage of goods on the continent. Its design and dimensions were conceived to meet European logistical standards and needs.

- On the other hand, the American pallet, also known as the GMA pallet (Grocery Manufacturers Association), originated in the United States. This type of pallet was designed to meet the needs of the consumer goods industry in North America. Its use has become widespread in the region due to its compatibility with American transport and storage systems.

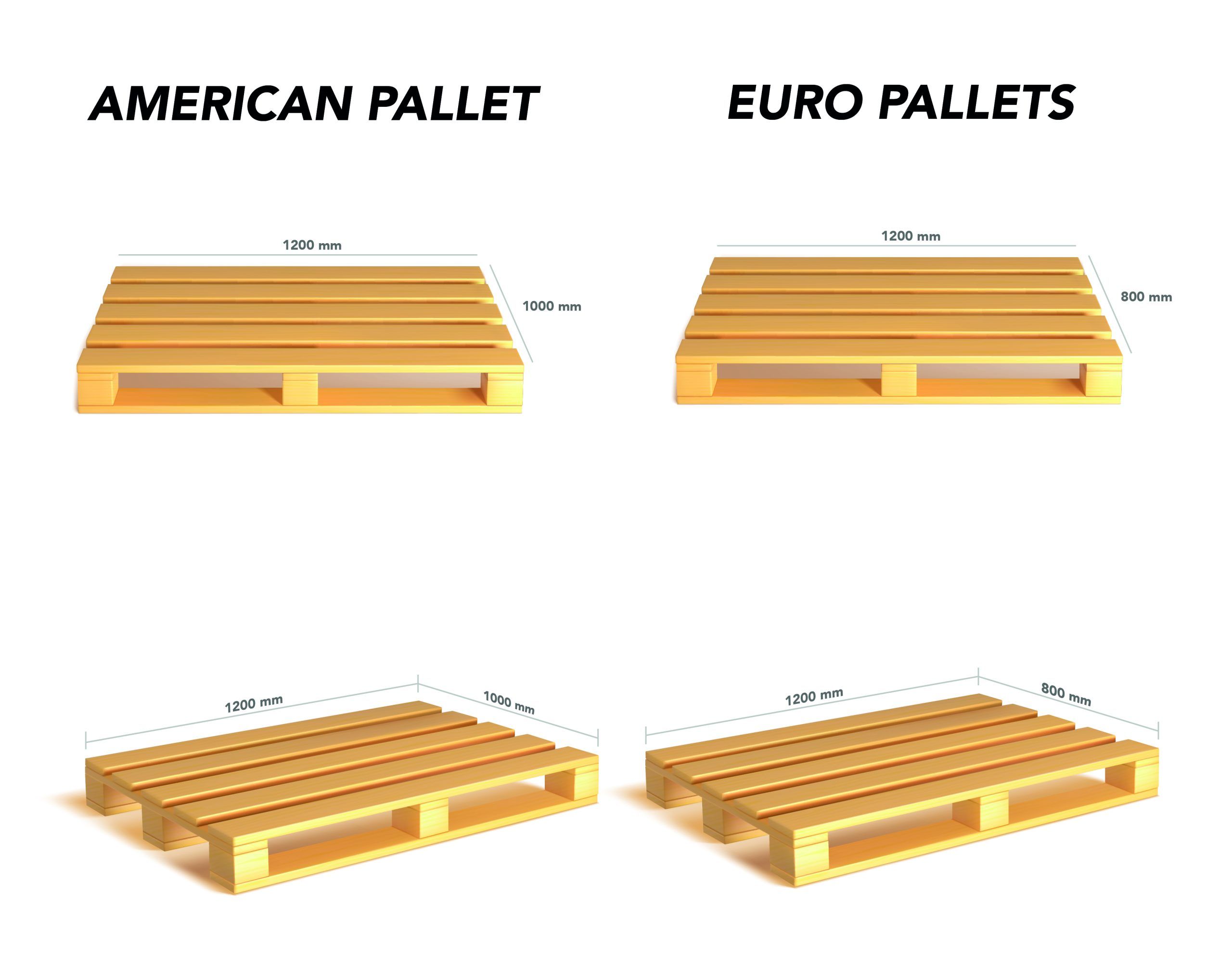

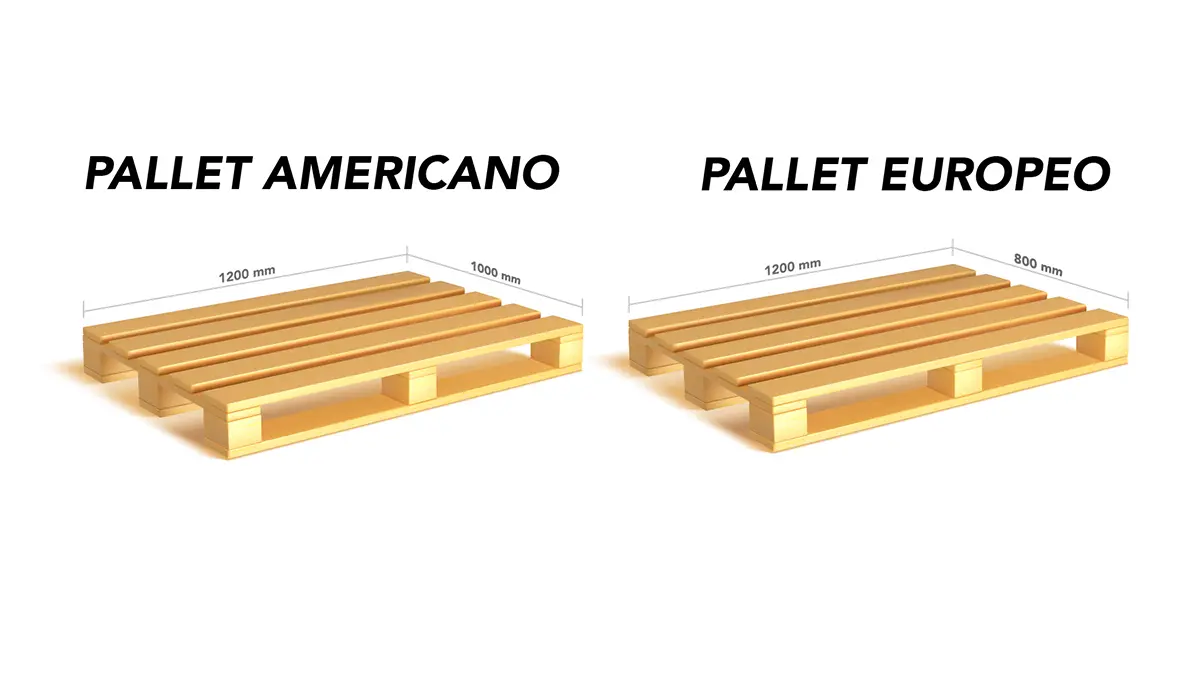

Dimensions and specifications

- The European pallet has standard dimensions of 1200 mm x 800 mm. These measurements make it ideal for use in European trucks and containers, optimizing the available space. Additionally, its load capacity is approximately 3,307 pounds, making it a robust and reliable option for a wide variety of products.

- In contrast, the American pallet has dimensions of 1200 mm x 1000 mm. This difference in size allows for better adaptation to North American storage and transport systems. The load capacity of the American pallet is similar to that of the European pallet, with a capacity of approximately 4,000 pounds.

Comparison of dimensions and load capacities

Although both types of pallets have similar load capacities, their differences in dimensions can influence space efficiency in warehouses and trucks. The choice between one or the other will depend on the specific needs of the company and the region in which it operates.

Materials and construction

- European pallets are usually made of high-quality wood, such as pine or spruce. This choice of materials ensures their durability and strength. Additionally, European pallets must comply with strict manufacturing and treatment standards to prevent the spread of pests and diseases.

- American pallets are also primarily made of wood, although other materials such as plastic or metal are sometimes used. The choice of material can vary depending on the specific needs of the industry and local regulations.

Differences in construction and design

One of the main differences in the construction of these pallets is the design of the boards and blocks. European pallets tend to have thicker boards and more robust blocks, giving them greater stability. On the other hand, American pallets may have a lighter design, making them easier to handle.

Uses and applications

- The European pallet is widely used in the food, pharmaceutical, and consumer goods industries in Europe. Its standardized design facilitates its use in automated storage and transport systems. Additionally, its robustness makes it ideal for heavy and bulky products.

- The American pallet is common in the consumer goods industry, especially in the retail and distribution sectors in North America. Its size and design make it suitable for use in warehouses and distribution centers, where quick and efficient handling is required.

Advantages and disadvantages of each type of pallet according to their use

Each type of pallet has its own advantages and disadvantages. The European pallet is ideal for automated systems and heavy products, while the American pallet is lighter and easier to handle. The choice between one or the other will depend on the specific needs of the company and the type of products it handles.

Regulations and certifications

- European pallets must comply with the regulations of the European Pallet Association (EPAL) and the ISPM-15 standard, which regulates the heat treatment of wood to prevent the spread of pests. These regulations ensure the quality and safety of pallets in international transport.

- American pallets must also comply with the ISPM-15 standard, as well as the regulations of the Grocery Manufacturers Association (GMA) in the United States. These regulations ensure that pallets are safe and suitable for use in the food and consumer goods industries.

Importance of certifications in international logistics

Certifications and regulations are essential to ensure the quality and safety of pallets in international trade. Complying with these regulations is crucial to avoid problems in the supply chain and ensure that products reach their destination in optimal conditions.

Most used racking systems for pallets

Selective Pallet Racking

Selective Pallet Racking Systems are a versatile solution adaptable to any type of load unit and forklift. They are ideal for storing both European and American pallets, offering great flexibility in storage.

Very Narrow Aisle (VNA)

Very Narrow Aisle (VNA) racking systems combine the advantages of conventional and compact racking systems. They allow high-density storage and easy accessibility to pallets, optimizing the available space in the warehouse.

Double Deep Pallet Racking

Double Deep Pallet Racking systems increase the available storage space by allowing two pallets to be placed in depth. This solution is ideal for warehouses with a high volume of products and fast rotation.

Drive-In and Drive Through Racking

Drive-in and Drive Through Racking systems are a high-density solution that maximizes storage space. They are ideal for homogeneous and low-rotation products, allowing large quantities of pallets to be stored in a reduced space.

Pallet Flow Racking (FIFO)

Pallet Flow Racking (FIFO) systems control stock rotation and make efficient use of space. They are ideal for perishable and high-rotation products, ensuring that the oldest products are used first.

Push-Back Racking (LIFO)

Push-Back LIFO (Last In, First Out) racking systems are a dynamic solution for stock management. They allow multiple pallets to be stored in depth, facilitating quick loading and unloading of products.

Shuttle Pallet Racking

The Shuttle Pallet Racking system is a high-density semi-automatic solution that uses motorized satellite carts to move pallets within the racking. It is ideal for warehouses with a high volume of products and fast rotation.

Impact on logistics and storage

The differences in size and design of European and American pallets can have a significant impact on logistics and storage. Choosing the right type of pallet can influence space efficiency, ease of handling, and supply chain optimization. It is important to consider the specific needs of the company and the products it handles when making this decision.

Conclusion

In summary, both the European pallet and the American pallet have their own characteristics and advantages. The European pallet is ideal for automated systems and heavy products, while the American pallet is lighter and easier to handle. The choice between one or the other will depend on the specific needs of the company and the type of products it handles. Additionally, it is essential to comply with regulations and certifications to ensure the quality and safety of pallets in international trade. Finally, AR Racking's racking systems offer versatile and efficient solutions for storing both types of pallets, optimizing space and improving logistics in the warehouse.