In the realm of modern industrial logistics—where efficiency, compatibility, and standardization are decisive factors—the American pallet stands as a pivotal element in storage and transport operations. With dimensions globally adopted across strategic industries such as food, pharmaceuticals, automotive, and retail, this pallet type not only facilitates goods handling but also directly impacts the design of industrial racking systems, logistics flows, and space optimization.

This article explores the American pallet’s structural role in the supply chain. We will examine its technical specifications, advantages over alternative formats, its impact on warehouse operational efficiency, and how AR Racking provides tailored storage systems designed to maximize its performance in demanding environments.

Concept and standardized dimensions of the American pallet

Also known as the GMA pallet (Grocery Manufacturers Association), the American pallet has become a benchmark in industrial logistics throughout North America and other regions that prioritize high-capacity storage and operational flexibility.

Its sturdy design, versatility, and compatibility with automated systems make it an essential tool for optimizing the supply chain in retail, food, and manufacturing industries.

The pallet features four-way entry access, significantly simplifying operations with forklifts and pallet jacks. This is especially valuable in high-turnover environments where speed and efficiency in goods handling are critical.

The American pallet integrates seamlessly into standard industrial racking and is compatible with automated solutions such as AS/RS systems, conveyors, and pallet shuttles, ensuring smooth and secure handling even in highly mechanized facilities.

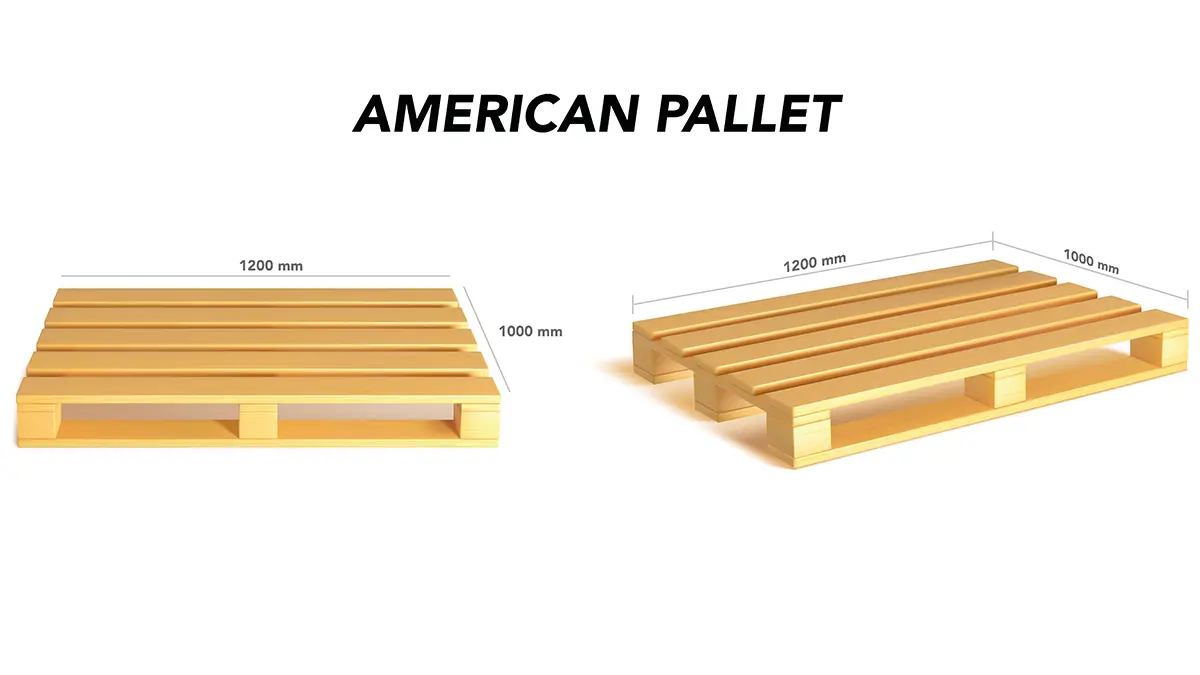

American pallet dimensions

The American pallet adheres to standardized specifications to ensure maximum interoperability across logistics systems. The most widely accepted dimensions are 1,200 mm in length by 1,000 mm in width—offering a slightly larger surface area than the European pallet (1,200 x 800 mm).

Height typically ranges between 144 mm and 160 mm, depending on the configuration and material used.

These measurements strike an ideal balance between load capacity and compatibility with ISO containers, transport trucks, and standard pallet racking. Their proportion also supports both block stacking and racking with varying depths.

Load capacity and weight

One of the American pallet’s key technical strengths lies in its load-bearing capabilities. It is engineered to withstand the high demands of modern logistics operations.

Under optimal conditions, a standard GMA pallet offers:

- Dynamic load capacity: Up to 1,500 kg—suitable for intensive handling and transport operations.

- Static load capacity: Exceeds 2,000 kg when stationary in storage systems.

- Empty pallet weight: Varies based on material—typically between 15 and 22 kg for standard wooden versions. Plastic or metal pallets have different weights depending on their design and strength.

These load capacities make the American pallet ideal for industries dealing with dense or bulky goods, ensuring structural safety in high-bay storage configurations such as self-supporting warehouses.

Types and materials of the American pallet

The American pallet is available in various materials and structural variants, each tailored to specific uses and industrial environments.

Wooden Pallet

The most widely used and cost-effective option. Commonly made from pine, poplar, or other treated woods, it offers solid mechanical resistance and easy repair. Best suited for high-turnover logistics and general applications.

Plastic Pallet

Designed for industries requiring high standards of hygiene and quality, such as food, pharmaceuticals, or cosmetics. Resistant to moisture and chemicals, with a long service life. Often used in automated processes and inventory management systems with high traceability.

Metal Pallet

Used mainly in heavy industries or hazardous goods storage. Extremely durable with superior load capacity. Ideal for demanding applications such as mobile racking or compact storage setups.

Variants include:

- Single-face or double-face pallets.

- Pallets with closed or open deck boards depending on the type of load.

- Reinforced pallets for extreme loads or automated use.

Across all versions, the American pallet remains a robust, versatile logistics solution that enhances both storage and transportation efficiency.

Strategic and operational advantages of the American pallet

Choosing the right pallet is far from trivial—it directly affects logistics costs, operational speed, and handling safety. The American pallet delivers significant advantages in several core areas of industrial warehouse management.

From an operational standpoint, its larger surface area maximizes pallet volume, especially beneficial in sectors handling wider or bulkier products. It's ideal for standardized palletized loads such as large boxes, drums, or display-ready packaging. Additionally, its solid structure and load capacity make it suitable for high-demand applications like high-volume warehouses or reverse logistics.

Strategically, the use of American pallets enables:

- Reduced transportation costs for full truckloads through better pallet space utilization.

- Greater mechanical handling efficiency, reducing picking and restocking time.

- Improved automation compatibility, thanks to symmetrical design and high durability in repetitive use.

- Cross-industry adaptability, simplifying supplier management and multi-client warehouse design.

Combined, these benefits boost supply chain efficiency, reduce errors, and enhance traceability and quality control.

Technical specifications and compatibility requirements

The American pallet requires specific logistical design considerations. Its compatibility with handling equipment and industrial racking depends on precise alignment between dimensions, load type, and storage system.

Key technical factors include:

- Entry type: Four-way access, but central blocks or runners may affect behavior on conveyors or rollers.

- Beam spacing: Racking beams must allow proper spacing to prevent pallet deformation under load.

- Material type: Wood, plastic, or metal—each responds differently to moisture, friction, wear, and compliance requirements.

- Automation readiness: Pallets must maintain tight dimensional tolerances and flatness for use in automated systems.

- Ventilation and hygiene: Certified plastic pallets are required in food or pharma sectors to avoid contamination and enable cleaning.

These considerations are especially critical in dynamic racking, mobile bases, or automated systems like shuttle or miniload.

AR Racking solutions compatible with American pallets

AR Racking designs and manufactures industrial storage systems specifically optimized for American pallet usage, ensuring maximum efficiency, structural safety, and technical compatibility.

Our systems are configurable based on load type, rotation frequency, and operating environment. Key solutions for American pallets include:

- Selective Pallet Racking: Ideal for warehouses handling diverse palletized loads, offering direct access and quick retrieval.

- Drive-In Racking: Maximizes space for homogeneous product volumes using 1,000 mm wide pallets.

- Pallet Flow Racking (FIFO): Gravity-based systems ideal for high-turnover logistics and fast-moving goods.

- Mobile Pallet Racking: Smart solution for space-limited environments, enabling dense storage without sacrificing access.

- Unit Load Rack AS/RS: For high-density, low-touch operations in fully automated settings.

All systems are built to international quality standards and can be tailored to meet specific safety or regulatory requirements, including food or chemical industry standards.

Implementation best practices

To fully leverage the benefits of the American pallet, a comprehensive approach is essential—considering both physical layout and operational flows. Recommended practices include:

- Ensuring dimensional compatibility between pallets, racking, and handling equipment.

- Using corrosion-resistant racking for wet goods or refrigerated environments.

- Integrating real-time stock management with WMS/LMS systems and location sensors.

- Designing aisle widths to support safe forklift maneuvering with 1,000 mm wide pallets.

- Conducting regular audits to remove damaged pallets that could compromise stability.

Thorough planning and expert technical support ensure long-term efficiency and durability of your logistics infrastructure.

Common challenges and solutions in handling American pallets

Despite their advantages, American pallets can present challenges depending on the environment:

- Incompatibility with existing European racks: Solvable with adapters or reconfigured beam levels.

- Overloading in racking built for Euro pallets: Requires recalculating capacities and reinforcing structures.

- Damage from intensive handling: Mitigated through more durable plastic or metal pallets.

- Dimensional variability affecting automation: Addressed by using certified pallets and automated inspection protocols.

These challenges can be overcome through precise technical specification, routine maintenance, and collaboration with a specialized partner like AR Racking.

American pallet and sustainable logistics

Standardized pallets such as the American pallet also contribute to logistics sustainability. Most are reusable, repairable, and recyclable—especially plastic or metal versions—reducing reliance on disposable materials.

Their automation compatibility improves energy efficiency, reduces handling frequency, and optimizes transport planning, lowering carbon emissions. AR Racking integrates these principles in sustainable warehouse design—combining productivity with environmental responsibility.

Conclusion

The American pallet is a technical standard in modern industrial logistics. Its durable design and compatibility with a wide range of storage systems make it an efficient, versatile solution. Implementing systems that maximize its potential is essential to achieving higher levels of productivity, safety, and sustainability.

Contact us—our expert team will advise you on the best racking configurations to unlock the full potential of the American pallet in your logistics operations. We deliver tailor-made solutions that guarantee efficiency, regulatory compliance, and a strong foundation for your warehouse’s sustainable growth.