AS/RS Systems for pallets

AS/RS Systems (Automated Storage & Retrieval Systems) are storage solutions using stacker cranes, pallet shuttles or other automated mechanisms tacker cranes or other similar automated mechanisms for handling loads.

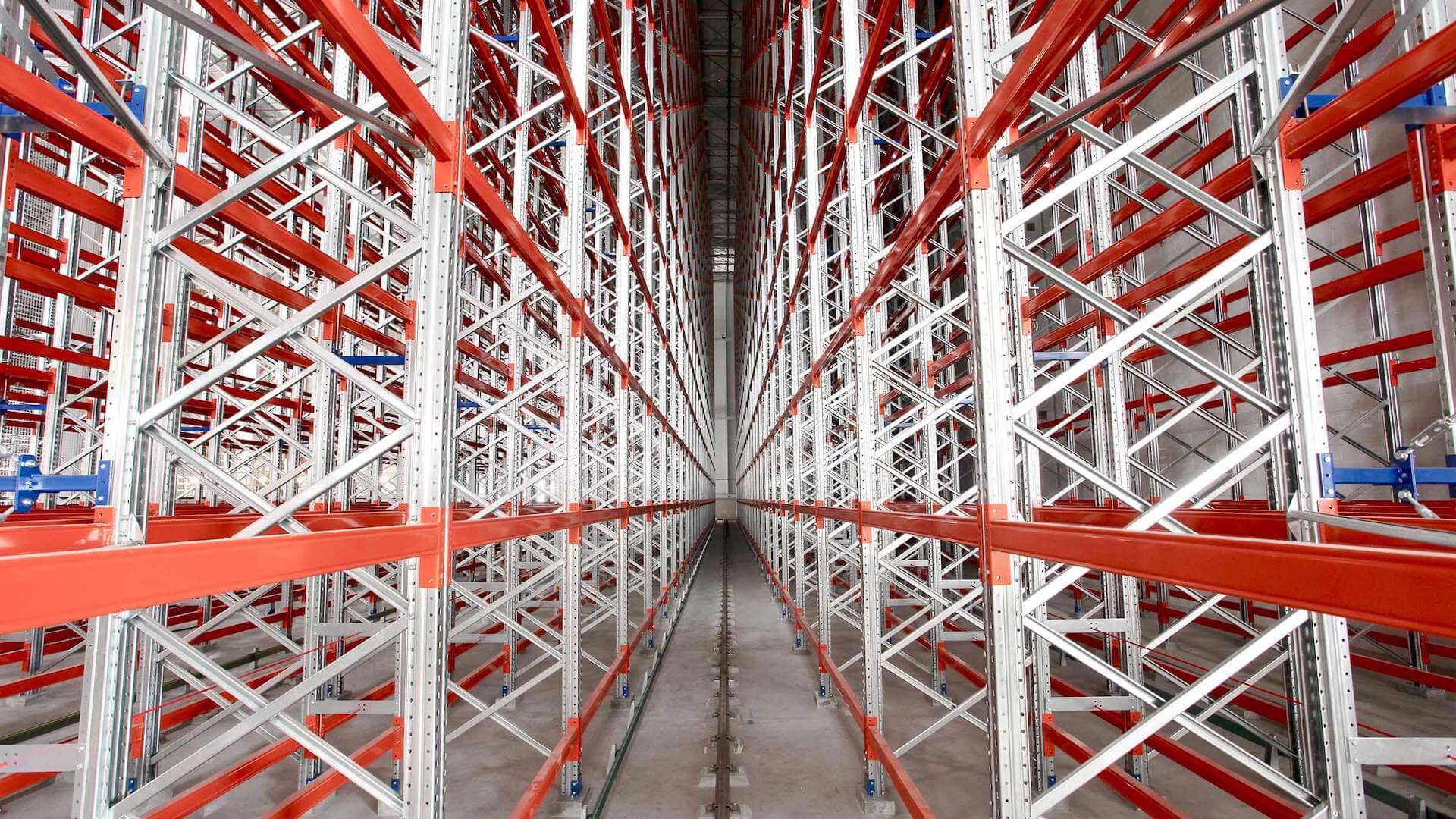

Automated warehouses have the same characteristics and advantages as clad-rack warehouses, except that they do not form part of the structure of the building.

It is a system that offer high density storage thanks to the reduction of operating aisles and to their capacity for increasing in height. They also use minimum response times.

AS/RS Systems reliability permits an immediate inventory of stored products and minimizes mistakes in the handling of loads. Structures for automated storage can be single-deep, double-deep or multideep with shuttles.

Automated pallet systems offer high density and large storage load capacity, reducing the number of work aisles and allowing the installation of high-bay racking. They also make it possible to manage the storage and retrieval of goods in a warehouse.

This system helps create product inventory almost instantly, while reducing errors and damage associated with load handling.

Automated warehouses incorporate technologies such as robots, conveyors, stacker cranes and warehouse management software, achieving optimization in the efficiency and precision of product storage and retrieval processes. Its objective is to reduce storage costs, increase productivity, and accelerate the delivery of products with greater precision and speed.

Additionally, storage automation enables more effective use of warehouse space by allowing safe and efficient stacking of products at height.

AS/RS Systems (Automated Storage and Retrieval Systems)

Automated warehouses use a centralised control system to monitor the inflow and outflow of products and goods. Firstly, the products are identified by a bar code or a radio frequency identification (RFID) system, allowing them to be traced in the system.

These products are then placed on pallets, which are automatically transported through a network of conveyors and stacker cranes to their destination in the warehouse.

Finally, when a product needs to be retrieved, the warehouse management system issues an order to the transport system, which locates and transfers the pallet to the removal point.

AS/RS Systems for pallets can either be Single, Double-Deep or Multideep Shuttle

Single-deep

In these types of automated warehouses, the stacker crane has access to the handling of a single pallet at depth, located next to the aisle.

Double-deep

In this case, more compact than the previous one, the stacker crane has access to two pallet units at depth on both sides from each aisle.

Multideep Shuttle

These automated warehouses consist of shuttles which, simultaneously and autonomously, load and position the goods independently.

This solution allows you to make maximum use of the space since the shuttle can access multiple pallets at depth. The shuttles can be fed from the main aisle by stacker cranes along the entire height, or by transfer cars which move along each aisle level.

Advantages and features of the AS/RS Systems:

- Offers maximum reliability and stock control.

- It boosts warehouse productivity and performance, reducing the number of movements, transportation activities and the use of space in the warehouse.

- It minimises the probability of human error and improves precision and speed in the retrieval process.

- Exploitation of warehouse space and surface area, since automated warehouses help reduce space, thanks to the fact that they can reach greater heights and reduce aisle size.

- Maximum adaptability. Automated pallet storage systems are a solution that is fully adaptable to the customer’s product specifications.

- It increases safety in warehouses and product handling, since conveyors and storage units are designed to handle and transport products safely, avoiding possible damage and errors.

- It optimises efficiency and productivity by reducing downtime, and increases storage capacity and streamlines product retrieval.

- Automated warehouses for pallets are optimal systems for cold storage. These warehouses are adapted to low temperatures, making them appropriate for the installation of cold stores and freezing chambers, which guarantee temperature control for the optimum preservation of stored products.

- It reduces maintenance costs and expenses by avoiding impacts on system structures.

- Automated warehouses can be modified or adjusted to possible new company needs that may arise over time.

Main applications of AS/RS Systems for pallets

Some of the main applications for which this type of systems could be particularly beneficial are:

- Distribution and logistics companies, who deal with high storage volumes and need to optimise efficiency in inventory management.

- Cold Stores: Facilities that require efficient management of perishable products and controlled temperatures that guarantee the preservation of products at low temperatures.

- Companies where speed, precision and inventory control in product retrieval are essential to meet market demand. That is, those companies with a large inventory that seek to optimise logistics operations.

Components of AS/RS Systems for pallets

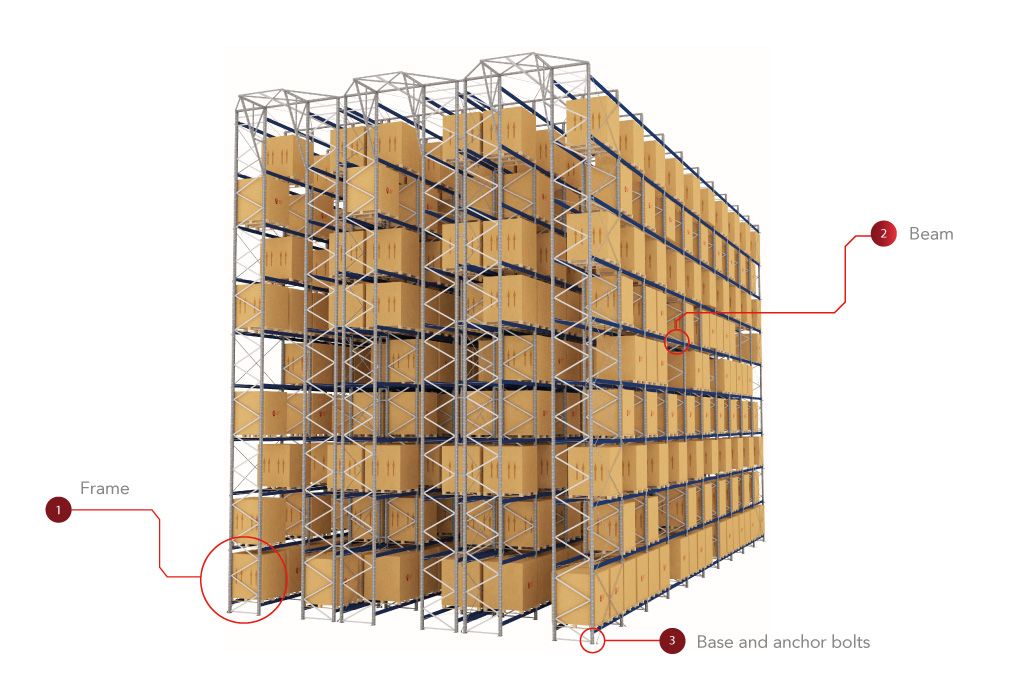

The Free Standing AS/RS Pallet Racking storage system is composed of a series of basic components essential for its efficient operation, such as the frame, beams and feet and anchors.

However, these are only the basic elements of the structure, in an automatic storage system there are numerous additional components that can be integrated according to the specific needs of each customer, thus allowing an optimal adaptation to different types of warehouses (Single-deep, Double-deep or Multideep Shutlle) and particular logistic requirements.

Main components of the AS/RS Systems for pallets

Frame

The frame is the vertical structure that supports the horizontal beams and provides the base for the storage of products or pallets. Frames are essential for the stability and strength of the system.

Beam

The beam refers to the horizontal beam that connects the uprights. These beams are essential for the structure and strength of the storage system and serve as support for pallets or other products stored on the racking.

Base and anchor bolts

The base and anchor bolts are components of the structure that guarantee the stability and safety of the system.

Automated warehouses for pallets meet the strictest European safety standards, and also come with AR Racking’s quality and innovation guarantee.

5-year Quality Guarantee

Our AS/RS Systems for pallets solutions for light and medium loads allows us to provide a 5-year quality guarantee against any type of manufacturing or hidden defect in the components of the main structure.

Component Traceability System

Since 2016, a significant part of our racking components has included a traceability system.

This system gives an identifying marker to the different components, which means we can know and document the origin of each component. This allows us to identify the component, its design and the raw material used in its manufacture.

Fully Automated Manufacture

The production of our industrial racking is fully automated. We use the latest generation profiling machines with continuous cutting process and laser measurement control, welding centres, painting and packaging processes, all fully automated, to guarantee the highest quality standards.

Designs in the R&D&I Centre

The design of the structures of our storage systems is carried out at our technology centre exclusively dedicated to R&D&I activities. We have an advanced engineering development area from which to offer suitable responses to the most demanding logistical requirements.

Tests at Research and Testing Laboratory

With the creation of our Research and Testing Laboratory in collaboration with the University of Mondragón, our technical team carries out continuous testing and analyses of products and materials to improve our racking. We use specialist software to simulate, calculate and research the efficacy of the geometries, and we perform exhaustive structural calculations on the behaviour of the systems already installed in different situations.

Quality certificates of our AS/RS Systems for pallets

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Galvanized steel corrosion resistance certificate: UNE EN ISO 14713-1

- Galvanized steel reaction to fire: EN 13501-1: 2007