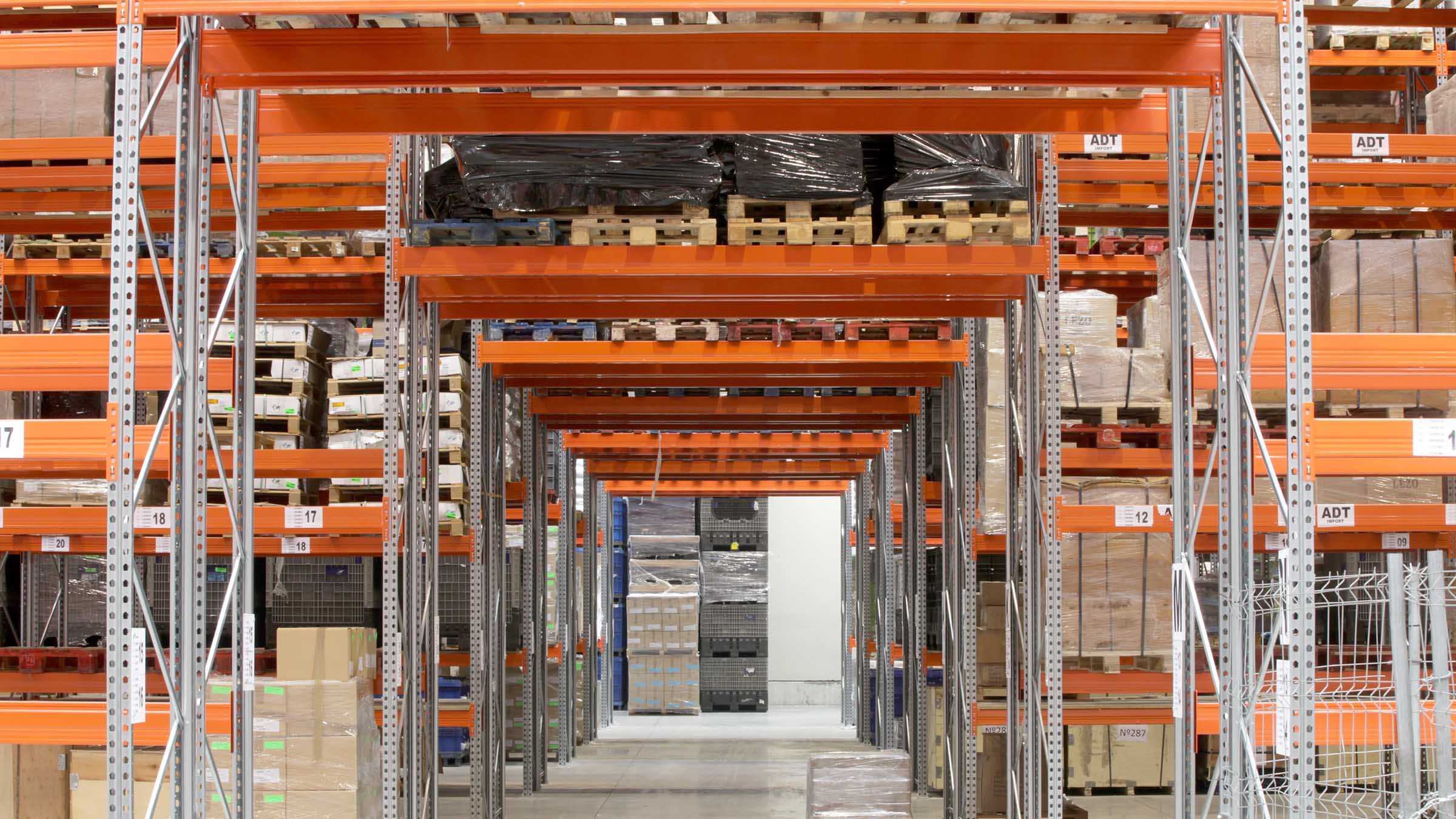

Racking Systems for Textile and Fashion Retail companies

The textile industry sector is advancing non-stop due to globalisation and online commerce. The omnichannel service which this sector requires along with continuous product availability, a unique shopping experience and optimal customer service, are all essential.

These are some of the notable logistical challenges that companies in the sector must face, since the textile sector supply chain has been altered with the need to create large distribution centres to meet consumer demand as a whole.

Having efficient warehouses will be essential to reduce goods handling and order placement times, and to optimise the inflow and outflow of products.

The textile sector has a series of specific logistical characteristics that require adapted storage systems, light shelving equipped with hangers, specific shelves for boxes of clothing or shoes, etc. Automation also offers excellent advantages to satisfy the demand for agile and efficient warehouses.

At AR Racking we have broad experience in the design and installation of storage systems to meet all the needs of the sector, adapting each textile requirement to the type of storage required.

Storage systems for the textile distribution and fashion retail industry

Stock rotation: priority

Storage systems in the textile sector must be prepared for high product rotation with different sales channels, differentiating between physical stores and online sales to the end customer. They are products with high obsolescence due to changes in fashions and tastes in society.

Manual picking systems

In the initial stages of the distribution chain, the goods are stored in pallet unit loads, but in the final phases the textile goods will be stored on industrial racking for medium or light loads. The goods will be stored in boxes, trays, hangers with hanging garments or other specific unit loads for manual handling.

Automated storage

Tighter deadline requirements resulting from the growth of e-commerce has forced many companies in the textile sector to install fully or partially automated storage systems, which, together with warehouse management software, facilitate the order preparation process. However, in companies with a lot of seasonal change in demand, the installation of an automated warehouse can pose risks due to its lower adaptability and versatility.

Combination of various systems

In the textile sector, it is common to install several storage systems in the same warehouse, due among other reasons to the specific unit loads required, such as hanging garments, folded garments, or garments also stored in cartons and pallets. Furthermore, textile companies generally work with product catalogues with highly variable and constantly changing references.

Characteristics of the textile distribution and fashion retail industry.

The textile sector distributes what are considered mass consumption goods, so its global importance in economic and employment terms is very high.

Changes in trends

The textile sector is one of the most demanding and competitive industries internationally, and is characterised by being global, by having a short product life cycle, by frequent changes in trends, and by having a significant impulse purchasing component.

Turnover varies notably according to each season and peaks in demand when sales are on for example, so the logistics processes must be modified at each time of the year.

Just in Time principle

Therefore, for textile companies, having efficient, optimised warehouses that allow correct product rotation will be of vital importance to be competitive in the market and to fulfil the “just in time” principle, as established by the stock management model of a textile warehouse.

The final stages of the supply chain of the textile sector are characterised by the need for manual storage or picking systems.

Recommended Industrial Racking:

Some common storage systems for the textile distribution and fashion retail industry are:

Longspan Shelving

Optimum system for the manual storage of small and medium-sized non-palletised products. They allow modulation and adaptation to any type of goods with various accessories and configurations, boxes, packages, hanging garments, etc.

Hanging garment shelving:

This is an adaptation of standard manual picking solutions with tubular beams that allow the storage of textile products on hangers.

Automated Pallet Warehouses

They are solutions that use stacker cranes or other automated mechanisms to handle the goods. They allow high storage density by eliminating the work aisles and streamlining the warehouse operations with minimum turnaround times.

Mini-load Automated System

It is the automated system for light and medium loads, as is usually the case with textile goods. It increases warehouse productivity and efficiency.

Adjustable Pallet Racking

Most common system for storage of pallet goods, with direct access to each unit load.