Warehouse productivity largely depends on the storage system installed, but not all storage systems are valid for all companies, products or processes. We focus below on the storage systems with direct access to the pallets or unit loads.

When goods are placed on a pallet for their storage, we are talking about pallet racking. Pallet racking is one of the most widely used procedures for homogenising the load in warehouses and logistics centres. The pallet enables the handling, treatment and transport of goods by forklifts.

Advantages of racking systems for pallets

Pallet racking has become one of the most important procedures in the logistics and transport of goods. It facilitates the grouping of goods, improves their handling and also makes it possible to manage high numbers of units.

In other words, pallet racking greatly helps to ensure stock uniformity along the supply chain. Goods are normally handled by forklifts or other handling equipment.

The main advantages of pallet racking are:

- It reduces preparation times.

- It reduces loading and unloading times and, therefore, minimises costs.

- It helps to keep product handling to a minimum.

- It helps optimise warehouse space.

- It favours stock rotation.

- It provides safety and security in handling goods.

- Fast location of goods.

Palletised loads need to be stored on industrial racking systems, which provide a guarantee of resistance and regulation of load levels to adjust them to precise stock volumes.

Storage systems with direct access to pallets

Although we have mentioned pallet racking as a standard method for the storage and transport of goods as a single unit, it is not possible to directly access pallets in all industrial racking systems and therefore the warehouse stock. There are compaction industrial storage systems, whose main characteristic is the maximum optimisation of the space, but without immediate and direct access to the pallets.

The following pallet storage systems enable direct access to the unit load:

Single-Deep Pallet Racking System:

Adjustable pallet racking systems are the racking systems for industrial loads par excellence. They use the pallet as the unit load support. Access is direct and is via structured aisles on each side of the racking bay.

It is the most universal solution, mainly due to the possibility of having direct access to each of the pallets stored.

It is a very versatile system that enables simple regulation of the load levels to adapt to any type of goods in terms of weight and volume. It is also characterised by being an effective, resistant and easy to assemble pallet racking solution.

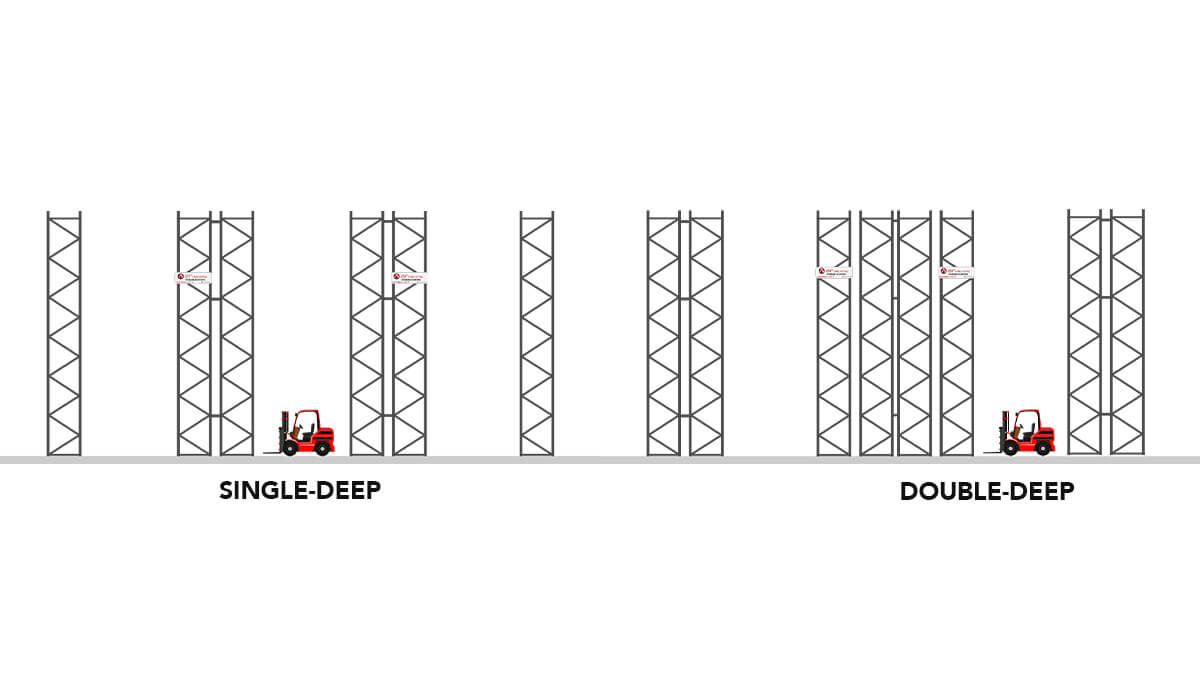

The adjustable pallet racking system can either be single-deep or double-deep, but the latter only enables direct access to the front pallet. The choice of one method or the other will depend on the number of pallets of the same reference or the inflow or outflow of the goods.

Depending on the handling and forklift equipment, there are two types of configuration:

- Class 400 or adjustable pallet racking system: wide aisle.

- Narrow aisle system for Class 300 or VNA (Very Narrow Aisle) System.

In addition, adjustable racking with direct access to the pallets comes with numerous optional accessories and elements that adapt to all types of storage needs.

Mobile Pallet Racking with direct access

In this case, the single adjustable pallet racking system, with direct access to the palletised unit loads, is mounted on a chassis that enables the movement of the racking bays. The racks move from one side to the other on the rails fixed to the floor to open a single access aisle for the forklift. Therefore, only the work aisle to which access is needed at any given time is enabled, but direct access is maintained to all the unit loads.

The opening of the work aisle to which access is required will be by means of electric motors situated at the base of the racking. The operator is in charge of giving the order to open the mobile racking using the remote control so that the forklift then has direct access to the pallets.

Every centimetre of the installation is exploited to the full, being an ideal alternative in a small area.

In short, it is a hybrid solution as it allows both the compaction of the space and direct access to the pallet.

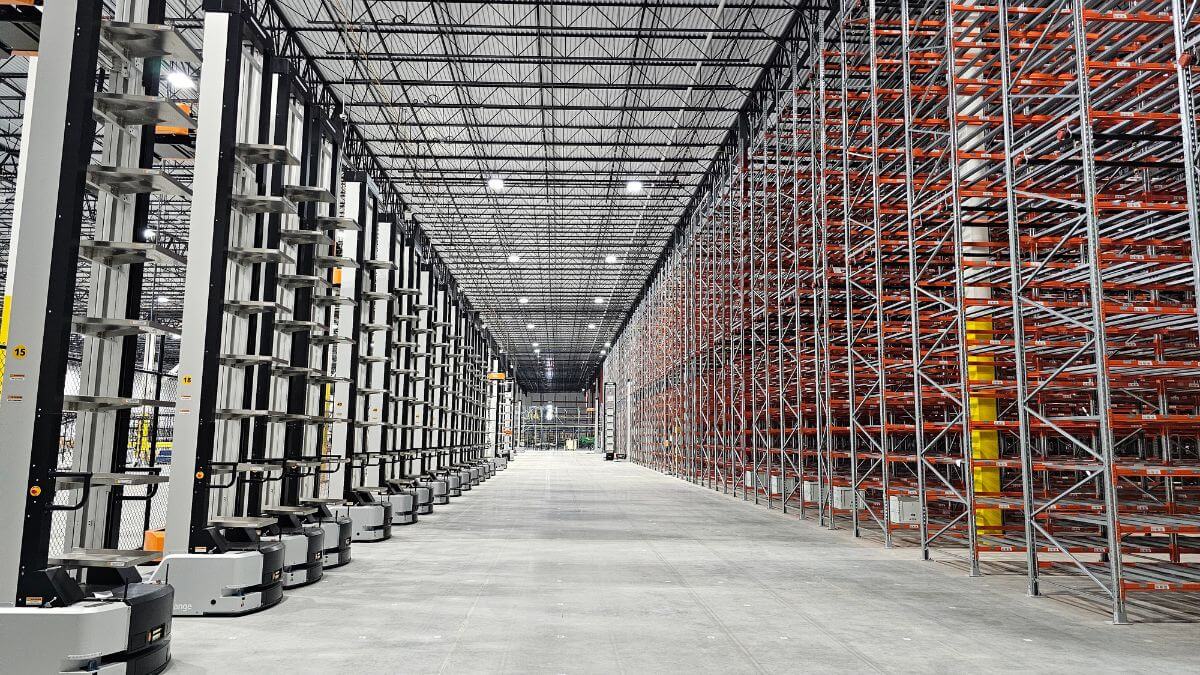

Automated system for pallets with direct access:

This involves the automation of the adjustable pallet racking system. In this case, instead of the forklifts, stacker cranes or other robotic mechanisms are used for direct access to the unit loads. Storage density is high thanks to fewer aisles while space at height is fully exploited, but the characteristic of direct access to the pallets is maintained.

The initial economic investment is higher than with the adjustable pallet racking system, but fewer technical and human resources are required to access the pallets, productivity is greater and goods are handled more quickly. The return on investment is therefore relatively immediate.

Automated warehouses for pallets are often clad-rack warehouses, whose main characteristic is that the racking forms part of the structure of the building.

More information can be found here about all the industrial pallet racking solutions.