Logistics processes are changing due to advances in technology and automation, thus increasing the productivity of warehouse management models. One of the most widely used methodologies to achieve this objective is load unitisation, which will be detailed below.

What is load unitisation?

Load unitisation is a process which has become increasingly important in recent years. This distribution method consists of grouping and ordering the goods received in the warehouse into larger load units for their future transport. This system makes it possible to maintain correct inventory control to be able to deliver the final product to the customer in the estimated time and in optimum conditions.

Objectives of load unitisation

- Keep the product in perfect condition so that it does not suffer any damage while it remains at the warehouse or is in one of the many phases of the Supply Chain.

- Streamline the logistics procedure of the goods. In other words, facilitate and expedite the transfer of goods safely, quickly and efficiently within the warehouse.

Most frequent unitisation models

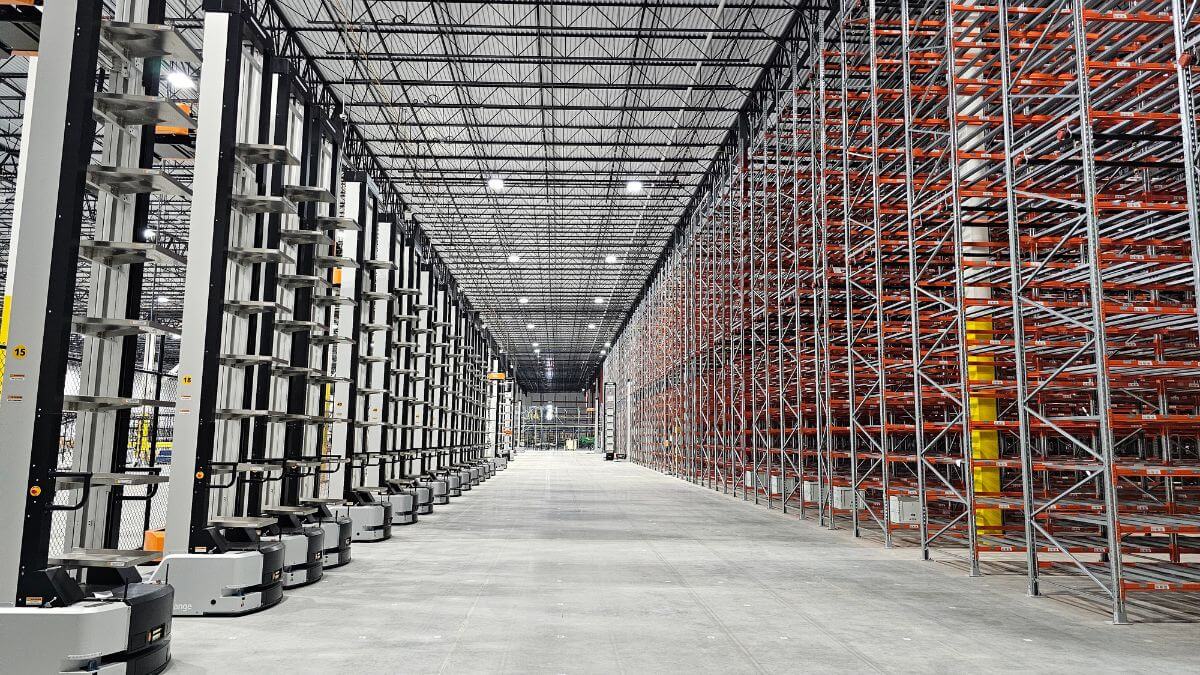

Pallet racking

Pallet racking is the first load unitisation model and consists of grouping together the smaller goods and placing them on top of a pallet to facilitate their transport, storage and use. It is vitally important to identify and choose well the type of pallet that you want to install, since the smoothness of the workflow will depend on it. Likewise, this method is standardised according to ISO 445, which describes the terms for pallets. However, the size and type of pallets is decided based on the size and weight of the goods and the place of transport.

Containerisation

The second method of unitisation, called containerisation, consists of using a container as a load storage and transportation unit, which allows the indivisible and safe handling of goods. The use of this method has greatly facilitated this stage of the supply chain since it expedites its transfer from one means of transport to another, thanks to its strength to be able to use it repeatedly. It is also considered to be a safer unit load than pallet racking because the container is only opened at the starting point and emptied at the final destination. As with the previous method, depending on the type of product to be stored, the containers can have different characteristics and materials, but they must meet the ISO 830 standard, whose objective is to help companies establish uniform criteria on management, service provision and product development in the industry.

Benefits of load unitisation

Ease of handling the goods.

Goods handling and transfer is far easier thanks to the grouping of the load, although this would be much more complicated and slower, generating possible final delivery delays.

Faster handling of the goods.

Warehouse tasks and truck loading and unloading are carried out more quickly.

Economic benefit

Since the load is grouped and ordered, it is less exposed to the possibility of theft and damage during distribution, resulting in lower insurance costs.

Product control and identification.

Continuous monitoring and correct identification of the products is easier thanks to unitisation, since the goods are classified in pallets or containers making their location faster.

Use of warehouse space.

By organising the load, the warehouse has optimal space, without any wasted space or clutter.

Safety and stability.

The products are perfectly attached to the pallets and containers to avoid impacts and damage during their transfer. The various materials handling teams move these items safely.

In conclusion, load unitisation allows safer handling of the load, reduces the possibility of theft or shortages, allows better control between product delivery and reception, and facilitates the identification and control of the goods. In the logistics world it is advisable to opt for these types of methods to facilitate and expedite the transfer of goods, as well as to ensure their integrity. At AR Racking we are experts in storage systems and our team will provide you obligation-free advice with the best solution for your business.